ALD EquipmentThis equipment is the system suitable for laboratory use to realize the precise step coverage deposition for uniform coating of each atomic layers.

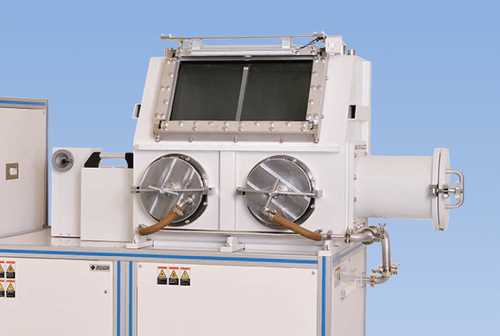

SAL3000

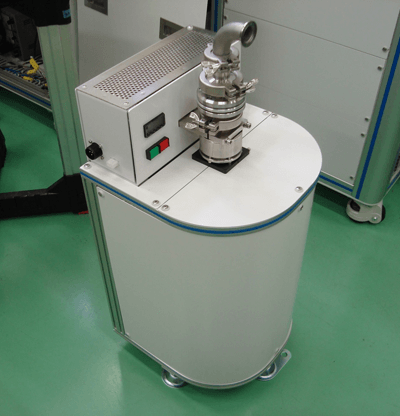

Space saving ALD with substantial functions

POINT

- Width reduced by 40% as compared to SAL3000 Standard

- Deposition up or down selectable

Outer dimension (Main unit)

W835mm×D700mm×H1644mm

| Precursor | Uniformity | Substrate heater | Combination |

|---|---|---|---|

| 4 lines (Max. 6 lines) | ≦±3% | 350℃ (800℃) | 〇 |

Outline・Application

This model was developed for R&D.

This equipment is the system suitable for laboratory use to realize the precise step coverage deposition for uniform coating of each atomic layers.

In addition to the conventional depo down, SAL3000 is equipped with the depo up function to reduce the particle adhesion onto substrates. Also the load lock chamber for automated substrate feeding and a glove box for vacuum replacement can be selected to meet the purpose.

The sample film kinds stipulated herein are just for the reference purpose only.

Features

【Features1】Deposition distribution with higher quality

Deposition performance is ≦±3% within Φ100mmarea.

The pin hole free layer deposition can be evenly performed for each atomics on the substrate surface.

The deposition for uneven surface or 3D shape can be suitable due to its step coverage.

【Feature2】Selectable Deposition Direction

SAL3000D(Deposition down) and SAL3000U(Deposition up) can be selected.

SAL3000D can reduce the risk caused by the adherence of particles on substrates.

【Feature3】Load Lock Chamber

LL chamber equipped with substrate automated feed function can be installed. The stable condition can be maintained with no atmosphere.

【Feature4】Glove box

Glove box can be installed to block the atmosphere. The height is 1200mm

for an easier operation through the window.

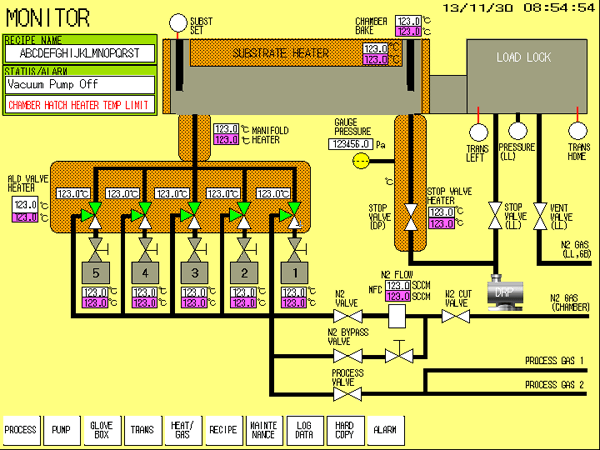

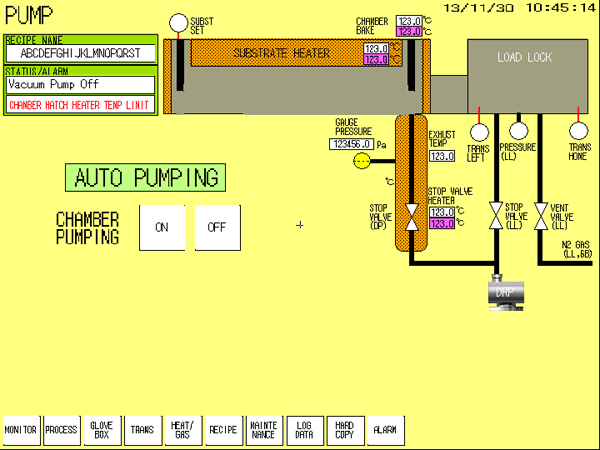

【Feature5】Easy-to-use program

Touch screen is placed at an elevation angle for better visibility and operability.

GUI(Graphical User Interface) is employed for an easier operation.

The deposition process can be stored up to 30 recipes and can be loaded into USB memory.

Monitor

<!–

ポンプ操作画面(ロードロック室付の場合)

–>

【Feature6】All in one design

The main unit and control box are designed as an integrated type.

【Feature7】Various options

Ozone generator, Exhaust gas treatment system, substrate heating(Max.800℃) and precursor heater up to Max. 200℃ are available as optional items.

【Feature8】Abundant connection ports for precursor bottles.

4 Precursor bottles can be accommodated as standard and two more precursors can be added as an option, so that various experiments can be carried out.

A standard bottle has a jacket heater for Max. 150℃. and one for Max.200℃ can be available as an option.

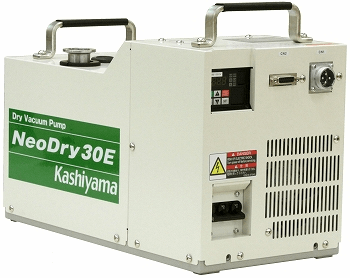

【Feature9】Dry Pump

A dry pump for 500L/min. is equipped with the system so that it can be used even in a clean room. N2 gas is recommended for long life, depending on process conditions.

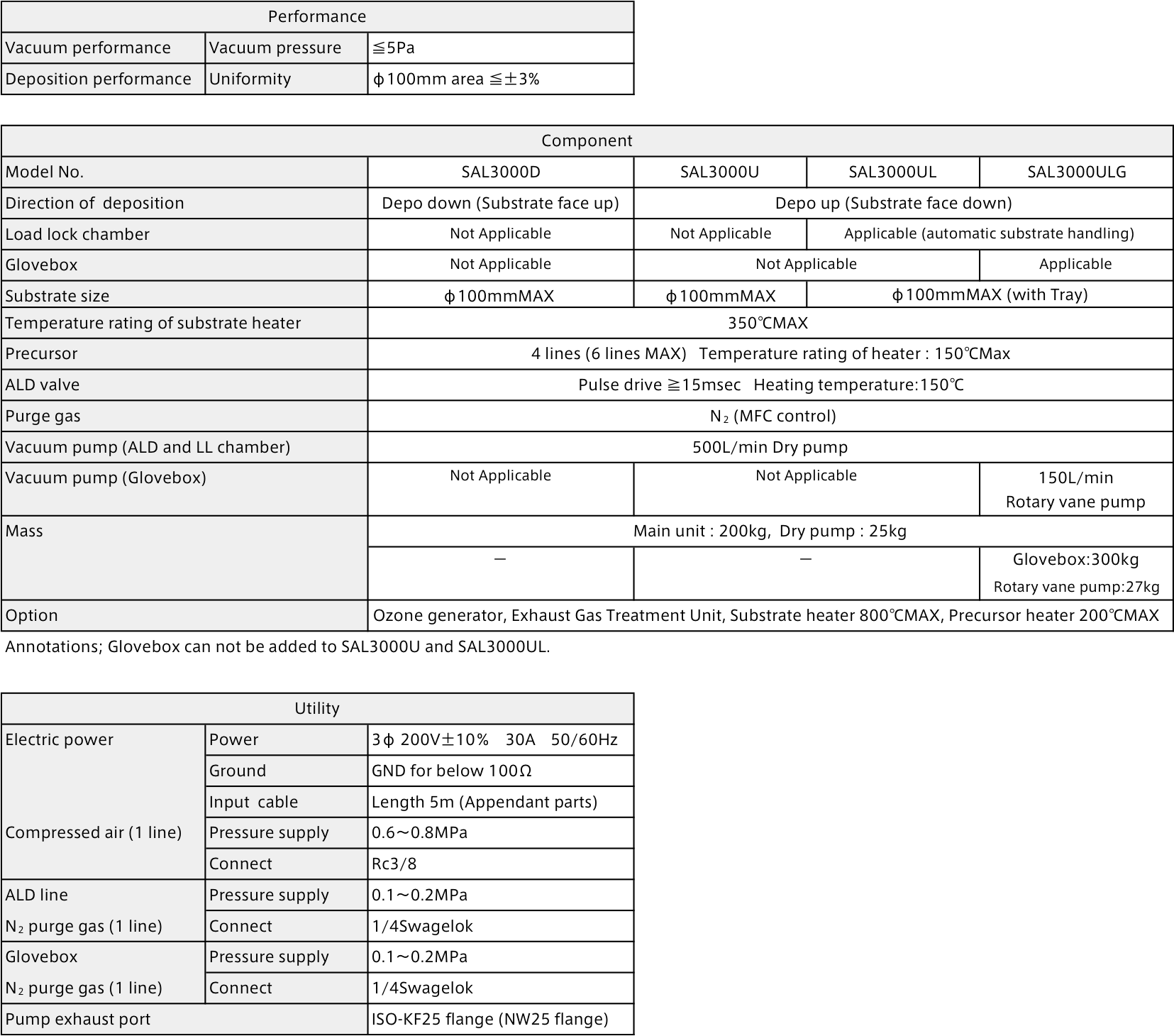

SAL3000 Specification

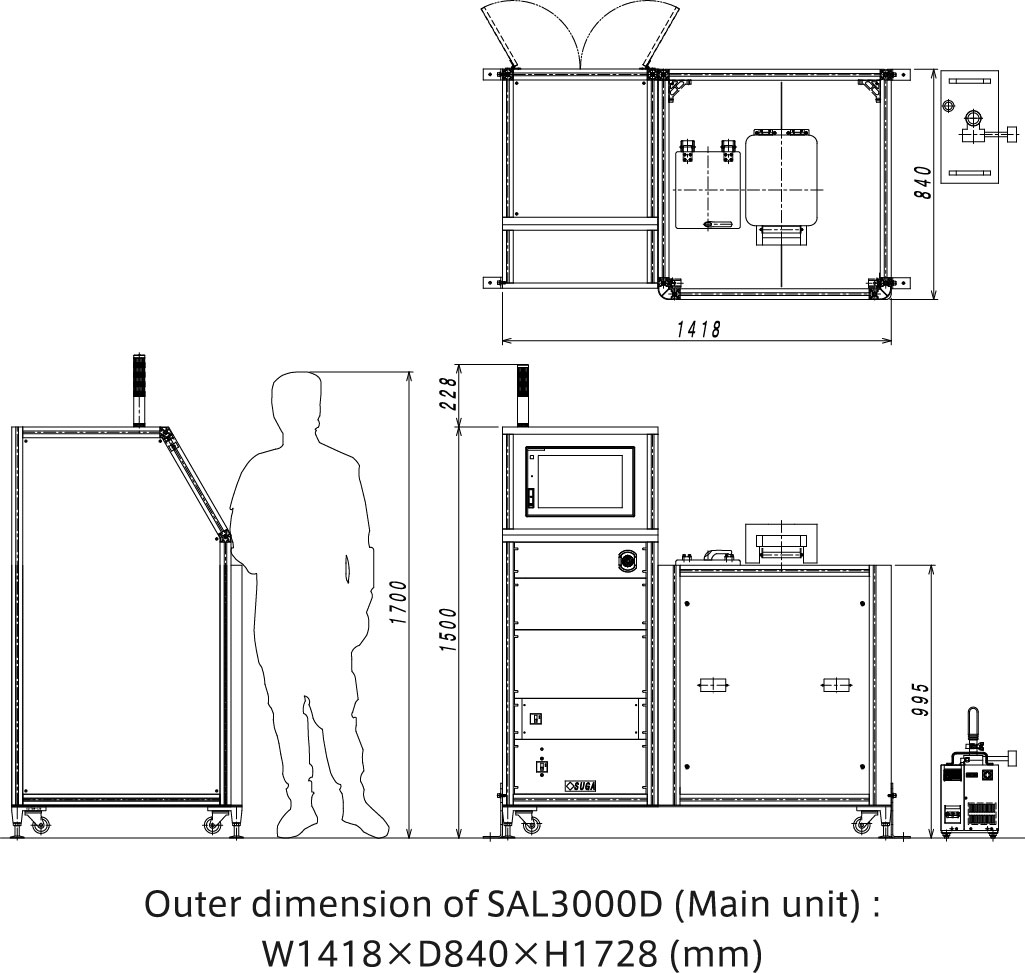

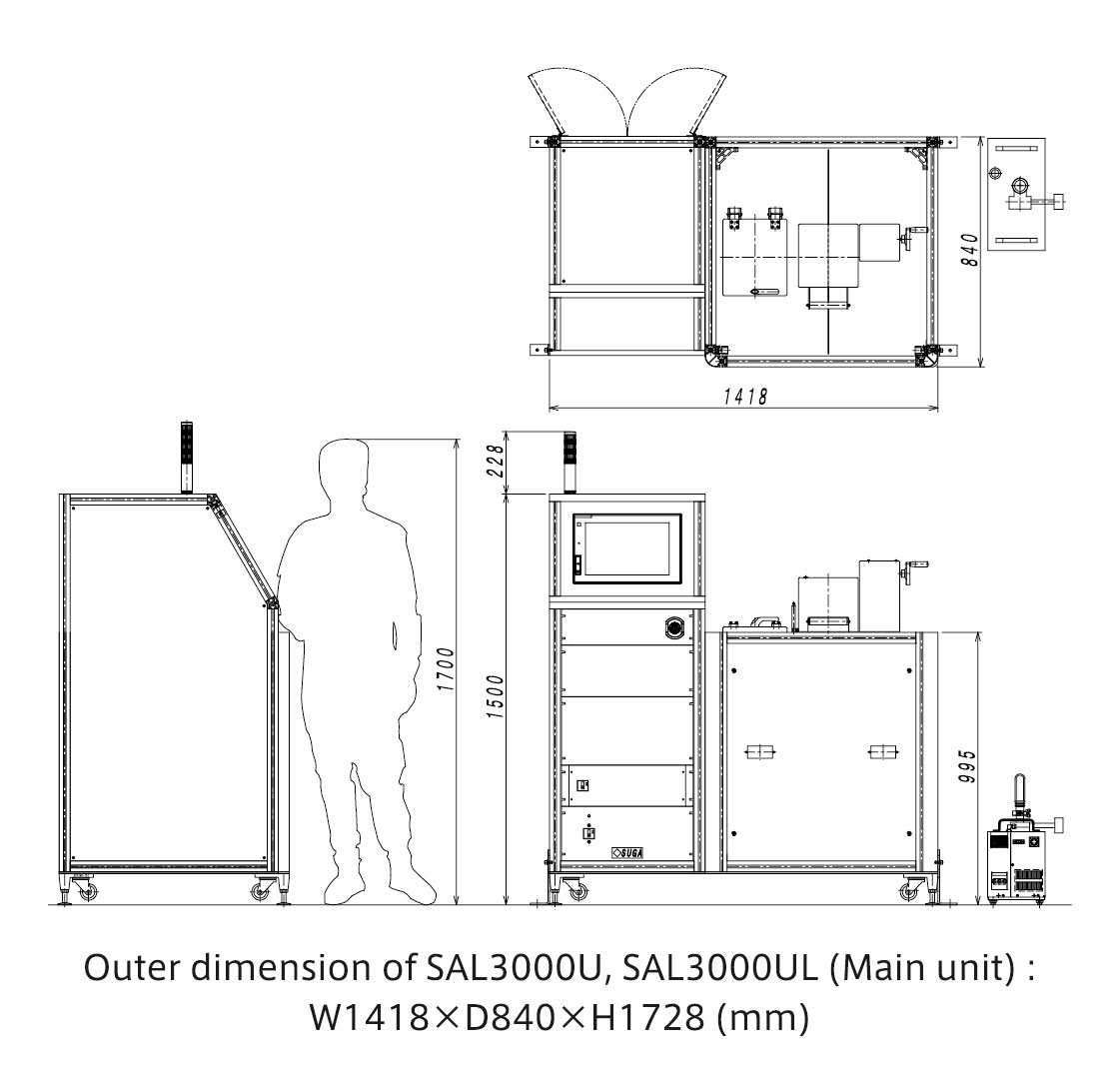

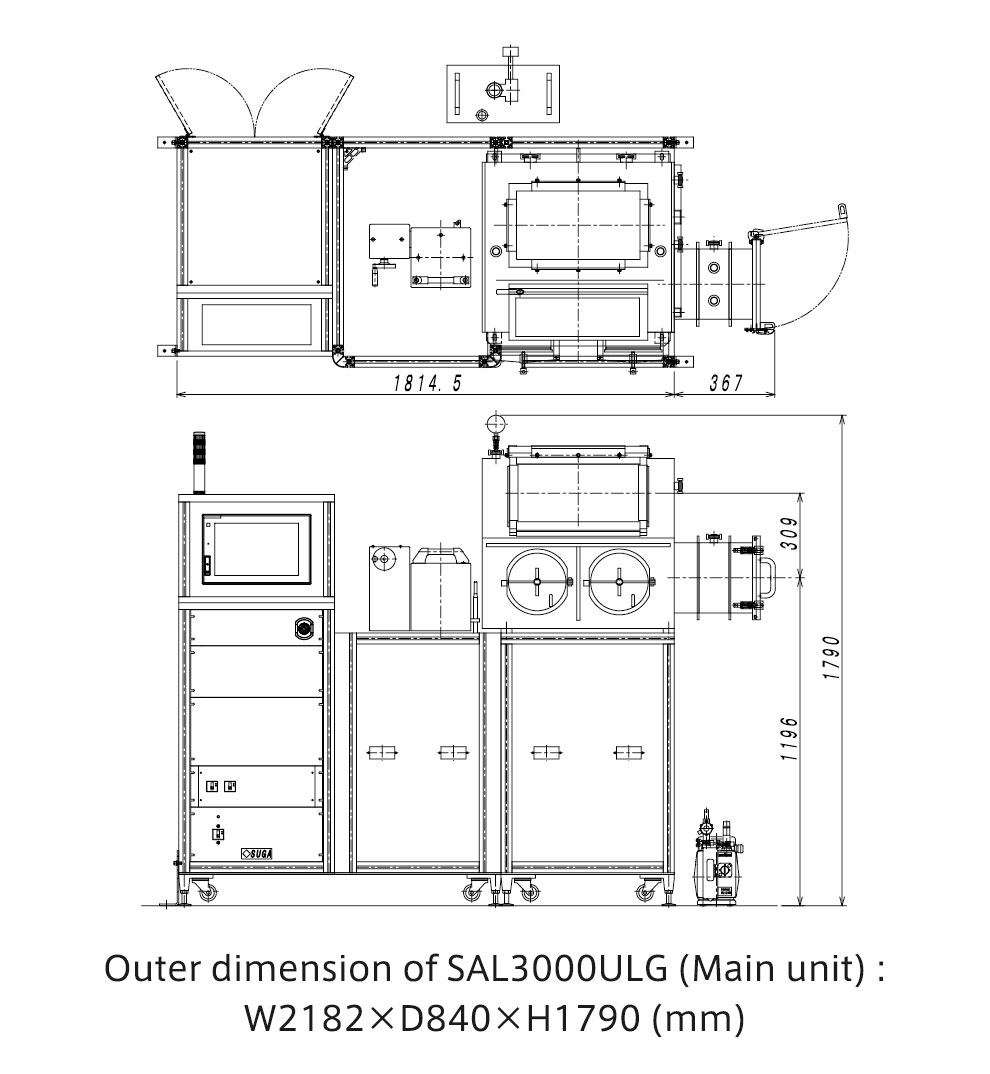

SAL3000 Outer dimension

Option

The following optional items are available.

【Feature1】Additional precursor

Max.6 precursors can be installed by adding two connection ports.

【Feature2】High Temperature Substrate Heating Mechanism

The normal heater is for Max.350℃. but it can be replaced with the one for Max.800℃ as an option. Annealing process may be made, although the dedicated annealing system is superior.

If the dedicated annealing system is required, SAN2000Plus is available.

【Feature3】Ozone Generator

This generator can be used instead of H2O to make Oxygen atoms react to make a thin film. The vacuum time can be reduced without H2O and the deposition can be made at the low temperature as well.

【Feature4】Exhaust Gas Treatment Unit

The precursor gas exhausted by ALD can be decomposed at high temperature heating. The effect can be obtained if the flow is within a range.

【Feature5】Heater for Precursor

The jacket heater for precursors (Standard Max. 150℃) is available to maintain steady vaporization of a precursor within a bottle. The jacket heater for precursor (Max.200℃) is available as well.

A thermocouple can control the heater setting temperature and actual temperature of precursor on the operation panel.