Sputtering system is deposition equipment using the sputtering method, which is classified as a physical vapor deposition (PVD) method within the category of vacuum thin film formation.

Thin films produced by sputtering equipment feature excellent adhesion to substrates, high reproducibility when repeatedly depositing films, and the ability to produce materials and alloys with high melting points. In addition, it can produce oxide and nitride films as well as metal films and insulating films, which are indispensable for functional materials such as semiconductors and electronic devices.

We design and manufacture high quality sputtering equipment that reflects the needs of our customers by applying the technology and strict quality standards we have developed over many years as a subcontractor for major vacuum equipment manufacturers to our own brand equipment.

[Characteristics of sputtering methods]

- The high collision energy of the material impacting the substrate results in a thin film with high adhesion strength.

- As the material flies linearly in approximately a constant direction, there is less film adhesion to non-substrate surfaces than with other deposition methods. However, it is difficult for the film to adhere to the sidewalls of uneven surfaces.

- Easy control of film thickness by adjusting various conditions such as supplying power and deposition time.

- A film of uniform thickness can be produced over a large area.

- High-melting-point materials and insulating films can also be deposited.

- Compared to evaporation systems, which melt materials at high temperatures when making alloys, changes in the composition of the material are less likely to occur.

- Reactive sputtering combining nitrogen, oxygen, hydrogen, etc. can also deposit compound films.

- Plasma cleaning (reverse sputtering) of the substrate deposition surface is also possible by applying high voltage to the substrate holder

- Lower deposition speed (deposition rate) than the evaporation method.

Contents

- 1 Product information on AGUS’s sputtering system [SSP3000].

- 1.1 [characteristic 1] High quality deposition

- 1.2 [characteristic 2] High-temperature substrate heating

- 1.3 [characteristic 3] RF power supply

- 1.4 [characteristic 4] Load-locking chambers that fit within an enclosure

- 1.5 [characteristic 5] Innovations in operability

- 1.6 [characteristic 6] Integrated body and control unit design

- 1.7 [characteristic 7] Wide range of options

- 2 Standard specifications for AGUS sputtering equipment [SSP3000].

- 3 Options for AGUS’s sputtering system [SSP3000].

- 4 Repair and remodeling of AGUS’s sputtering system [SSP3000].

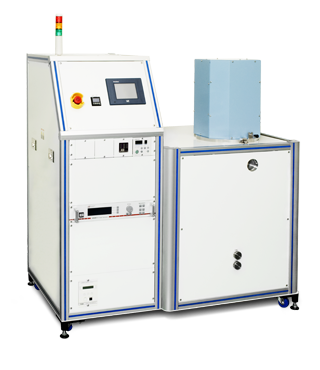

Product information on AGUS’s sputtering system [SSP3000].

High-performance, multi-functional sputtering system

It is active in a wide range of fields, from research and development to low-volume production, for metallic films, insulating films, conductive films, insulating films, protective films, reflective films, alloys, catalysts, coatings, circuits, batteries, MEMS and new materials development.

[characteristic 1] High quality deposition

Equipped with three 2-inch diameter magnetron cathodes (with shutters), it achieves high-quality film deposition with a film thickness distribution of ±3% or less within a φ100 mm area, which is the highest quality in Japan (according to our survey).

The equipment is capable of single-layer, multilayer and alloy deposition.

[characteristic 2] High-temperature substrate heating

The substrate heating function, which determines film quality, can be heated by a radiation heater to MAX 800 °C (monitor temperature) as the option, compared to the standard specification of MAX 300 °C.

The surface temperature of the actual substrate can be verified by pre-shipment inspection.

[characteristic 3] RF power supply

The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

![[characteristic 3] RF power supply](https://agus.co.jp/en/wp-content/uploads/2023/04/SSP3000_2.png)

[characteristic 4] Load-locking chambers that fit within an enclosure

The design allows an optional automatic load lock chamber to be installed inside the enclosure without changing the width dimension of the main unit (D=1418 mm).

The projecting parts related to the transport system are ingeniously housed in the control cabinet trestle.

In case of the sister model, SSP3000Plus, if a load lock room function is added, the STR2000 transfer unit must be purchased separately and coalesce into a large unit, but the floor space occupied by this machine (SSP3000)remains the same.

It excels in terms of implementation and maintenance costs.

![[characteristic 4] Load-locking chambers that fit within an enclosure](https://agus.co.jp/en/wp-content/uploads/2023/04/SSP3000_3.png)

[characteristic 5] Innovations in operability

The touch panel is positioned at an elevated angle and designed for better visibility and easy operation.

The GUI (Graphical User Interface) type program is adopted for intuitive understanding by operators, providing both visibility of various statuses, including operating status, and operability for easy adjustment of valves and setting items.

It is equipped with a touch panel program that is both easy to operate and safe, complete with various interlocks and alarm functions.

In response to the ever-changing nature of research and equipment modifications, the program itself is designed to be easily modified, thereby reducing design costs when changing programs.

[characteristic 6] Integrated body and control unit design

The design combines the main unit with the deposition chamber and exhaust system, and the electrical control system mount into one unit.

Compared to equipment with a separate main unit and control rack, the rear of the equipment has a cleaner appearance with no excess wiring exposed.

It’s easy to move and reduce man-hours (=expenditure) when relocating or changing the room layout after installation.

[characteristic 7] Wide range of options

The SSP3000 can be supplemented with a variety of options.

Depending on the performance and membrane quality required by the customer, these options can be added at the time of installation or by remodeling after installation.

Some combinations may not be applicable, so please contact us for details.

Standard specifications for AGUS sputtering equipment [SSP3000].

![Standard specifications for AGUS sputtering equipment [SSP3000].](https://agus.co.jp/en/wp-content/uploads/2023/04/SSP3000_4.png)

Options for AGUS’s sputtering system [SSP3000].

1. Magnetic deposition

When depositing films with magnetic materials such as iron (Fe), a stable plasma discharge cannot be achieved with standard magnetron cathodes.

This allows a choice of cathode specifications for magnetic materials.

Even after the equipment has been installed, both magnetic and non-magnetic materials can be used by replacing parts.

2. High temperature substrate heating

The substrate heating function, which determines film quality, can be heated by a radiation heater to MAX 800 °C (monitor temperature) as the option, compared to the standard specification of MAX 300 °C.

The surface temperature of the actual substrate can be verified by pre-shipment inspection.

3. Support for thin targets

Our cathodes are based on a ø50.8 mm x t3 mm geometry, but manufacturing a 3 mm thick target of expensive material can result in high expenditure.

If you want to reduce target expenditure or know from the outset that the number of depositions will be small, shields and target holders for thin targets such as 1 mm and 2 mm are available, so please contact us if you are concerned about the cost of the target you are using.

※Some materials are difficult to discharge on thin targets.

※Note that if a thin target is sputtered in combination with the standard parts for 3 mm thickness, an abnormal discharge may occur in the extra gap created between the target and the shield, and deposition may not be achieved.

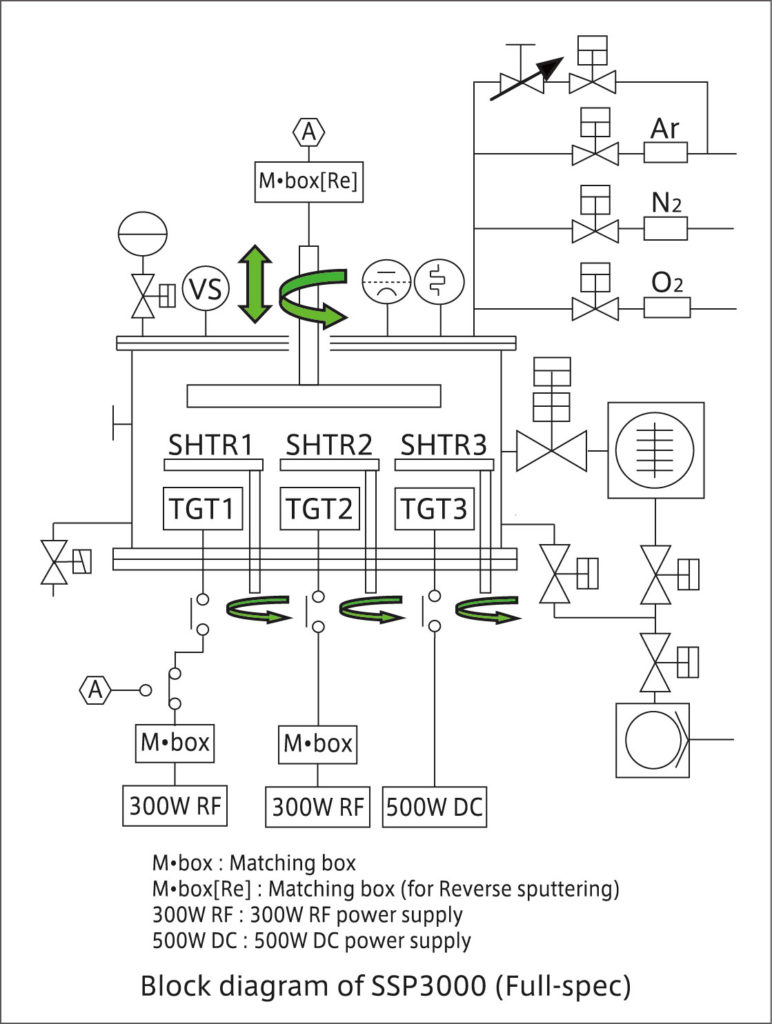

4. Sputter power supply

One RF power supply and one DC power supply each can be added. Three-way simultaneous discharge sputtering with a maximum of two RF power supplies and one DC power supply is possible.

Simultaneous discharges are used to increase deposition rates and produce alloys.

5. Automatic harmonizers

Changing the manual matching box of the RF power supply to an auto-matching box maintains the discharge under optimum conditions.

Fully automatic deposition by recipe is also possible.

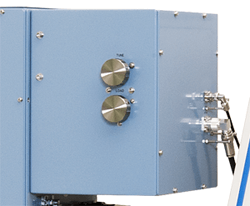

6. Reverse sputtering mechanism

The addition of a reverse sputtering mechanism makes it possible to remove oxide films on the substrate surface as a pre-treatment for deposition and clean the surface.

Matching box for reverse sputtering (manual)

※The photo shows the SSP3000Plus, but the matching box is installed in the same way at the top of the chamber.

7. High speed substrate rotation

The board rotation speed can be increased from the standard 5 rpm to 50 rpm.

It is expected to be effective in improving film thickness uniformity and in the deposition of alloys by multiple simultaneous sputtering.

8. Additional gas introduction systems

Two additional process gas introduction systems can be added, making a maximum of three systems.

This option is required when performing reactive sputtering by introducing oxygen, nitrogen, etc.

9. Up-grade to a dry pump

The auxiliary pump can be replaced from a rotary pump to a dry pump.

Basically dry pumps are required under the condition of cleanroom installation.

Our selection of non-contacting, multi-stage Roots dry pumps ensures maintenance-free, clean exhaust air for a long time after installation.

Repair and remodeling of AGUS’s sputtering system [SSP3000].

Maintenance services for our equipment are handled by technicians dispatched from our head office in Hokkaido and from a base in Shizuoka Prefecture.

Preliminary discussions regarding modification and maintenance are handled by sales representatives stationed in Hokkaido and the Kanto region.

Even after the equipment is installed, we are fully prepared to meet any request.

Within the stipulated warranty period after delivery of the equipment, we will repair free of charge any initial defects or other faults that are not covered by certain conditions stipulated by us (failure due to natural disasters or improper use).

For more information, please contact us.

[Example of repair and maintenance menu]

- Routine maintenance of equipment and service response in case of malfunction

- Remodeling or adding functions to equipment and modification of the program software associated with such work

- Relocation of equipment and layout changes

- Operational training (e.g. when the person in charge of operations is replaced)

- Purchase of consumables

- Cleaning and re-blasting of the film on shielded components

- Questions to be resolved by email, telephone, etc.

[Modification]

Even after the equipment has been installed, we can also provide services related to modifications due to changes in the content of experiments or conditions of use.

Examples of modification

- Combined with another device via a transfer unit (Plus series)

- Various functional additions/changes and parts replacement

- Production of sample holders for special shapes

- Program improvements and updates

- Additional gas introduction systems

- Replacement of rotary pumps with dry pumps

- Larger auxiliary pumps

- Additional cooling water circulator (chiller)

- Other remodeling and On-site services on request