Sputtering system employs the sputtering phenomenon.

Ar ions are bombarded onto the target under a plasma discharge and the target material tapped out by them is deposited by the sputtering phenomenon.

It is used in research and development applications such as metal films, insulating films, conductive films, protective films, reflective films, catalysts, coatings, circuits, batteries, MEMS and advanced materials.

Founded in 1946 as a repairer company for fishing boats, SUGA manufactures and sells vacuum equipment and is now expanding its activities mainly to R&D equipment for universities and research institutions.

In this article, we will introduce the sputtering system manufactured by SUGA, which we hope you will find useful.

Contents

Active in research and development, including the development of metal films and new materials!

【SSP1000・SSP2000Plus・SSP2500G・SSP3000・SSP3000Plus】

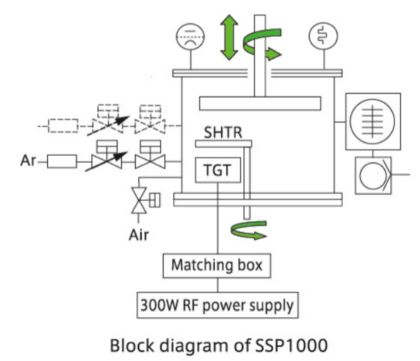

SSP1000〈Cubic Sputtering Equipment〉

Characteristics

Equipped with one 2-inch diameter magnetron cathode (with shutter), the performance is less than ±5% film thickness distribution within φ100 mm.

This entry-level model does not compromise but employs the same cathode structure as the superior model.

- The dice-shaped chamber (deposition chamber) can change the deposition direction into three different way.

- The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

- The automatic vacuum pumping system reduces the risk of accidental damage to the equipment during operations involving the exhaust system, making the equipment safe to use.

- Various instruments and operating system components are efficiently arranged.

- Interlocks are set up so that the plasma discharge is not powered on unless a number of conditions are met, such as the proper operation signal of the exhaust system pump, pressure information from the vacuum gauge and cooling water sensor signal.

- Both stacked and parallel (horizontal) arrangements are possible to accommodate a variety of installation environments.

- Users who regularly handle vacuum equipment (especially sputtering equipment) can set up and start up the equipment by themselves, as it is not difficult to do so.

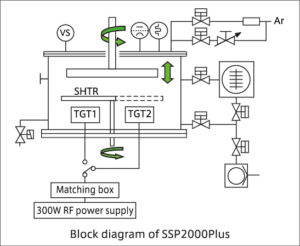

SSP2000Plus〈Sputtering Equipment (Expandable type)〉

Equipped with two 2-inch diameter magnetron cathodes (with shutters), with a film thickness distribution of ±5% or less within φ100 mm.

- For the function of substrate heating, which determines film quality, a heater with a standard specification of MAX 300°C is installed, enabling high quality film deposition.

- The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

- The system can be combined with Plus series sputtering, ALD, annealing and deposition equipment, enabling a variety of deposition processes without exposing the substrate to the atmosphere.

- It combines visibility regarding various statuses, including operating status, with easy operation for adjusting valves and setting items.

- The slim tower shape makes it easy to move and reduce man-hours (=expenditure) when relocating or changing the room layout after installation.

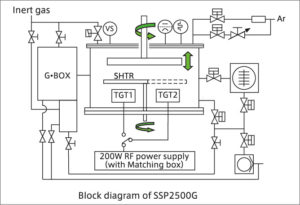

SSP2500G〈Sputtering Equipment with Glove Box〉

By switching the discharging cathode, this equipment can also be used for layered deposition.

- Equipped with a simple glove box (made of acrylic resin) that can be vacuum-replaced, allowing substrate replacement and target removal and attachment without exposure to atmospheric moisture or oxygen.

- The 13.56MHz 200W RF power supply made in Japan is equipped with an auto-matching function as standard so that fine adjustments are made automatically during plasma discharge.

- It combines visibility regarding various statuses, including operating status, and operability for easy adjustment of valves and setting items.

- No exposed wiring on the back of the unit for a clean appearance. It’s easy to move and reduce man-hours (=expenditure) when relocating or changing the room layout after installation.

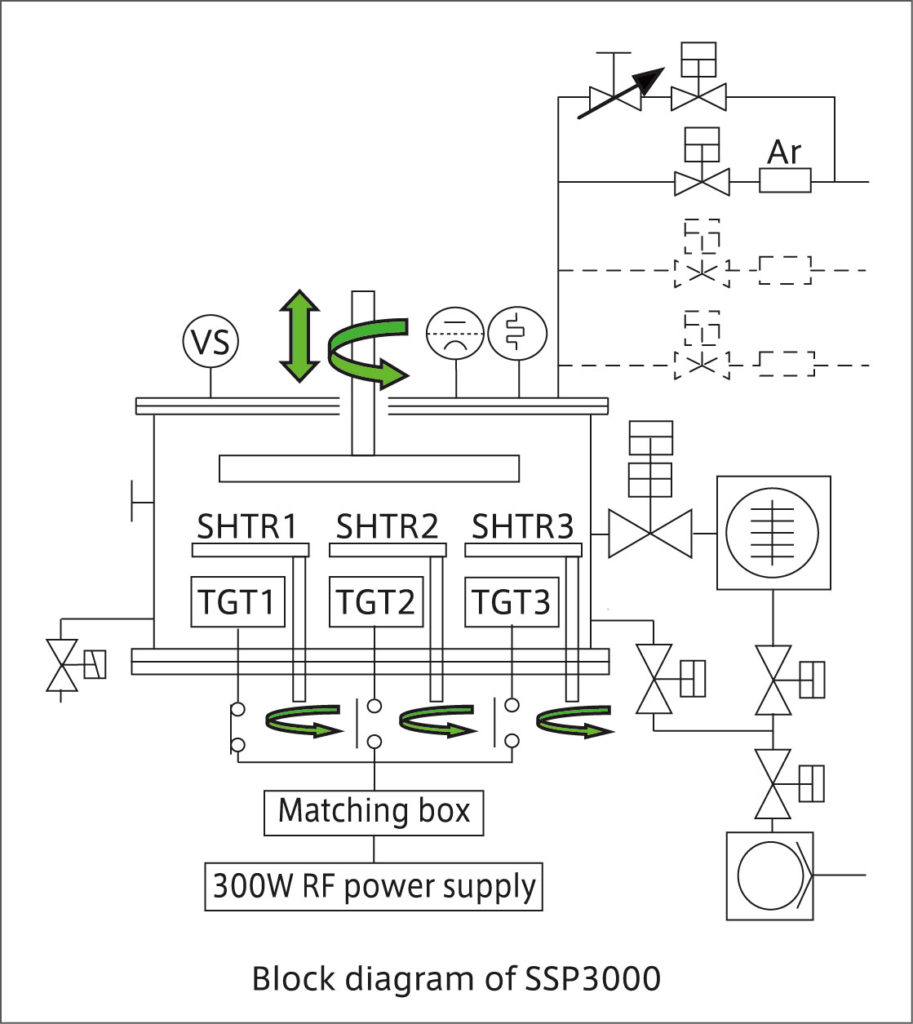

SSP3000〈Sputtering Equipment〉

Equipped with three 2-inch diameter magnetron cathodes (with shutters), it achieves high-quality film deposition with a film thickness distribution of ±3% or less within a φ100 mm area, which is the highest quality in Japan (according to our survey).

- The substrate heating function, which determines film quality, can be optionally heated by a radiation heater to MAX 800 °C (monitor temperature), compared to the standard specification of MAX 300 °C.

- The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

- It is designed to allow an optional automatic load lock chamber to be installed within the enclosure with the width dimension D=1418 mm of the main unit remaining unchanged.

- The touch panel is positioned at an elevated angle and designed for better visibility and easy operation.

- No exposed wiring on the back of the unit for a clean appearance. It’s easy to move and reduce man-hours (=expenditure) when relocating or changing the room layout after installation.

- Various options can be added depending on required performance and membrane quality.

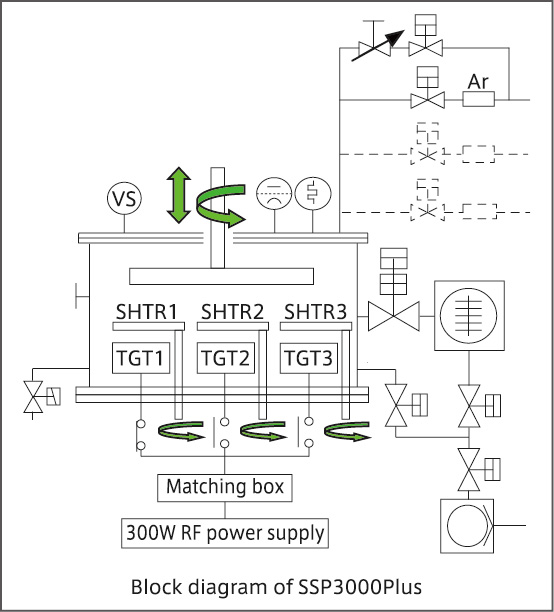

SSP3000Plus〈Sputtering Equipment (Expandable type)〉

As the same as SSP3000, high-quality deposition is achieved. In addition to this, it is also capable of single-layer, multilayer and alloy deposition.

- The substrate heating function, which determines film quality, can be optionally heated by a radiation heater to MAX 800 °C (monitor temperature), compared to the standard specification of MAX 300 °C.

- The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

- A port for expansion is provided on the side of the unit, which can be connected to the transfer unit STR2000 to provide a load lock function cabinet.

- Designed with visibility and operability in mind, it combines visibility regarding various statuses, including operating status, with easy operation for adjusting valves and setting items.

- No exposed wiring on the back of the unit for a clean appearance. It’s easy to move and reduce man-hours (=expenditure) when relocating or changing the room layout after installation.

- As well as a wide range of options, the structure allows easy connection to ALD and annealing equipment via the transfer unit STR2000, even after the installation.

Summary

SUGA which manufactures vacuum equipment, uses annealing equipment for film quality improvement applications after film deposition as vacuum equipment, and provides vacuum and piping components required for the configuration of vacuum equipment and vacuum facilities.

We also offer support for service, repairs and modifications, please contact us for more information.