In this episode, we will introduce a noteworthy cutting-edge trend SPS technology that has the potential to have a significant impact on the development of new materials in the next few years.

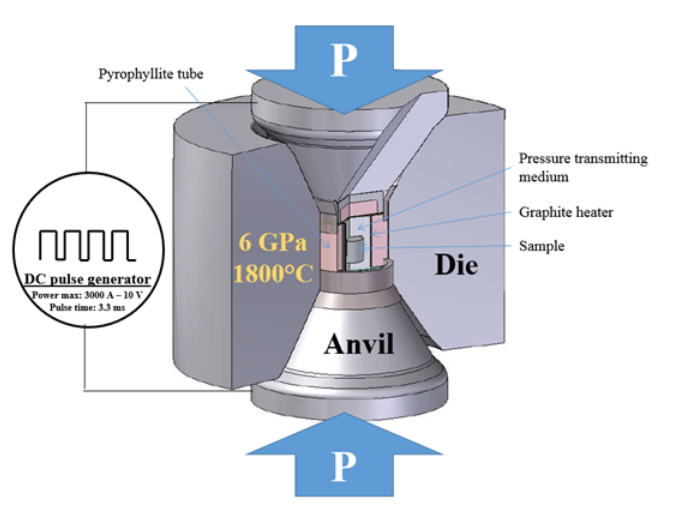

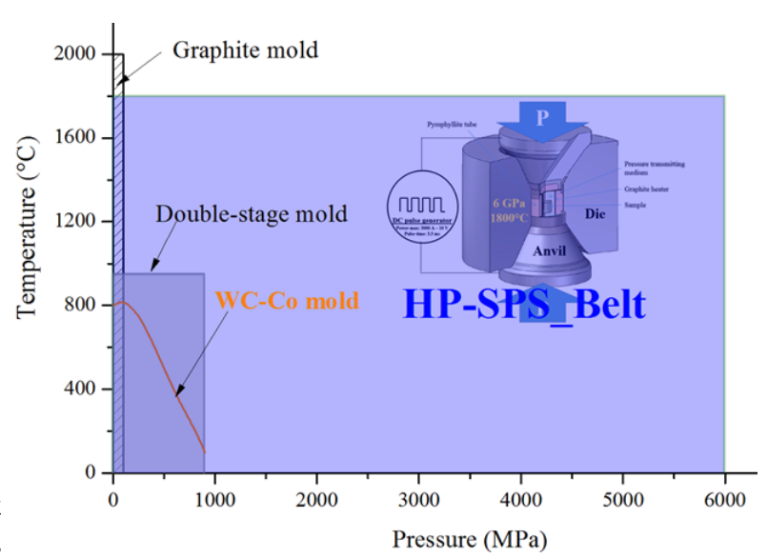

This is the new technology for SPS that uses ultra-high pressure to apply SPS sintering instead of conventional level of pressurization. In general, the pressure range for SPS is several MPa to 200 MPa for standard graphite structures, and ~1 GPa for special graphite, composite, and sintered cemented carbide materials. On the other hand, at the Ultra-High Pressure SPS, materials are sintered under ultrahigh pressures of 6 to 8 GPa.

The ultra-high pressure synthesis technology has been used as a synthesizer for ultra-hard materials such as c-BN since around the 1960s, and is also used as a production method for industrial diamonds. Recently, ultra-high pressure SPS has been developed by combining this ultra-high pressure synthesis technology with the pulsed current heating of SPS. Ultra-high pressure SPS further accentuates the unique features of SPS and enables the sintering of materials that cannot be reached by conventional and standard SPS techniques.

Advantages of Ultra-High Pressure SPS include

- Ultra-high pressure makes it possible to densify materials at lower sintering temperatures.

SPS is characterized by its ability to sinter at lower temperatures than conventional sintering methods, but even lower temperatures are possible, enabling the suppression of grain growth and the effect of nanostructure-controlled sintering. - Low-temperature densification sintering of temperature-sensitive compositions (ex. HAp)

- Sintering of high-density low-temperature phase materials (ex. Anatase-TiO2)

- Sintering of materials with stable structures under high pressure (ex. Diamond)

- Higher density sintered materials can be obtained by applying ultra-high pressure.

- Chemical reactivity is improved by applying ultra-high pressure (ex. Borides, Nitrides). (ex. Borides, Nitrides, Carbides.)

This ultra high-pressure SPS technology was developed by researchers at Univ. Bordeaux, CNRS, Bordeaux INP, ICMCB, a French national scientific research center located in Bordeaux, a port city in southwest France famous for its wine. Click here to get the original article.

CNRS, founded in 1939, is the largest government basic research institute in France with a total of 31,637 faculty members (including 24,552 regular faculty, 11,137 regular researchers, and 1,639 doctoral students).

The National Institute of Advanced Industrial Science and Technology (AIST), Japan’s largest national research institute, has 2,945 full-time employees (2,258 research staff, 687 administrative staff), 3,135 contract staff, and 7 directors) and approximately 5,000 researchers from companies, universities, and external research institutions (total number received in FY 2020). The CNRS has a large number of researchers from research institutes as well as research centers.

In CNRS, there are many joint research units and Institut de Chimie de la Matière Condensée de Bordeaux(ICMCB) is one of those kinds working with universities.

Ultra-high pressure SPS is the new technology that is expected to be adopted as an industrialization/production method in the future. We, SUGA Co., Ltd. signed a partnership agreement with ICMCB in 2018 with a view to the future potential of this technology. The need for this technology has been increasing more and more in recent years and it becomes Cutting-Edge Trend of SPS Technology .

In this agreement between ICMCB and SUGA, ICMCB is appointed in charge of the development of this technology and SUGA is in charge of the design and manufacture for the equipment and industrial approach in order to promote the technological development of Ultra-High SPS technology and its penetration into industry through the cooperation of both parties.

Please note that this is a direct agreement between ICMCB and SUGA.

I believe this is proof that the researchers at ICMCB have a high regard for our technical and developmental capabilities.

Please do not hesitate to contact us if you are interested in the application of our Ultra-High Pressure SPS. Together with the researchers and technicians at ICMCB, one of the largest research institute in France, we will assist you in the research and production of your products.

You will receive the following support

- Practical demonstrations at ICMCB

- Experimental testing of materials by Ultra-High Pressure SPS experiments at ICMCB

- Optimization of the Ultra-High Pressure SPS process for your application

- Technical development of SPS equipment under high pressure

- Examination of other technology applications to meet your needs

With ICMCB’s Ultra-High Pressure SPS equipment, combined with our expertise in SPS and high-pressure technology, we can propose appropriate solutions to everyone interested in this technology.

In the next issue, we would like to discuss some of the applications of SPS.