Relationship between sputter deposition and substrate temperature.

Did you know that the substrate on which the film is deposited is also heated during sputtering deposition?

Sputtering is a deposition method in which a high voltage is applied to the target material in a space filled with the inert gas such as Ar, causing the atomized Ar to collide with the target, thereby expelling the atoms, which adhere to the opposing substrate to form a thin film.

During this process, the Ar ions strike the target and it generates heat, so the target needs to be constantly cooled by running cooling water at the backside of the target material.

There is 50-300W plasma in front of the substrate within 50-70mm. Such substrate is placed in a vacuum condition, which means that it’s surrounded by insulation. (In case of our SSP series)

We need to be cautious, as the more the film is deposited, the higher the substrate temperature rises, and depending on the type of substrate, the temperature limit may be exceeded.

Fluorescent lamps are good example of plasma, and some people may have experienced that even a 40W fluorescent lamp commonly used in the home becomes so hot that it almost burns when you touch it.

Imagine if there is a 50-300 W fluorescent lamp about 50-70 mm in front of you.

You can get an idea of how much heat the face in the substrate position can generate.

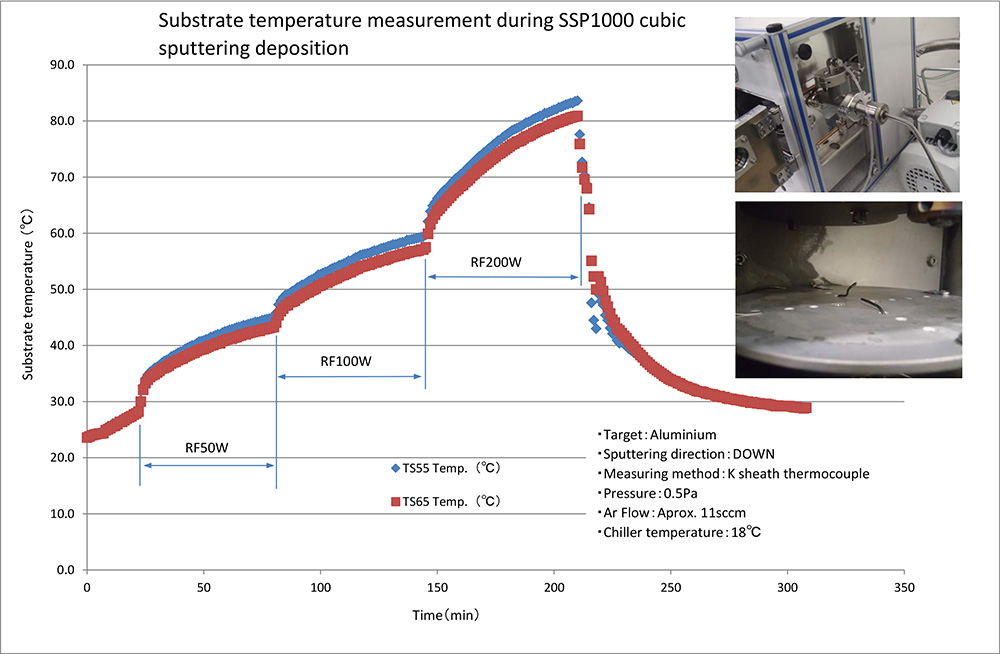

Actual measurement results of the relationship between sputter deposition and substrate temperature (SSP1000 cubic sputtering equipment).

We have used our in-house cubic sputtering equipment SSP1000* to measure the temperature of the side being deposited during deposition.

Although temperature differences arise depending on the size of the substrate on which the film is deposited, the diagram below should give an idea of the temperature rise.

SSP3000/SSP3000Plus sputtering equipment with a substrate holder cooling mechanism is also available to reduce temperature rise during deposition.

SSP1000: Entry model of sputtering deposition does not equipped with a substrate water-cooling mechanism.

Actual measurement results of the relationship between sputter deposition and substrate temperature (SSP1000 cubic sputtering equipment).

Deposition conditions

- Model: SSP1000 cubic spatter equipment in-house demo machine

- Target: AL (aluminum)

- Sputter direction: depot down.

- Temperature measurement method: K-sheath thermocouple

- TS distance (target-subst. distance) = 55 mm, 65 mm

- Discharge pressure: 0.5 Pa.

- Ar flow rate: about 11 sccm

- Chiller temperature: 18°C

- Temperature near the substrate after about 60 minutes of changing the input power of the RF power supply.

- About 45°C at 50 W.

- About 60°C at 100 W.

- About 85°C at 200 W