Chemical etching on sample surfaces can be carried out in an enclosed space.

This simple wet-etching equipment has compact desk top type design and three spray nozzles (for chemical etching, pure cleaning and N2 drying), each spraying time and spraying sequence can be set as desired.

It is useful in cases where the dry etching equipment appears to be too much, or when simple etching processes are required at R&D experimental sites..

Wet etching equipment mainly targets oxide (SiO2) and nitride (SiN) films.

- The chemical spray is applied directly from the above to center of the sample.

- The cleaning water spray and N2 spray nozzles are angle-adjustable.

- Forms a uniform spray distribution even at low flow rates.

Contents

- 0.1 Product information on [SWE1000].

- 0.2 [characteristic 1] Composition of in-container components.

- 0.3 [characteristic 2] Spraying time

- 0.4 [characteristic 3] automatic processing

- 0.5 [characteristic 4] rotational control

- 0.6 [characteristic 5] touch panel

- 1 Standard specifications for [SWE1000].

- 2 Repair and modification of [SWE1000].

Product information on [SWE1000].

[characteristic 1] Composition of in-container components.

The inner parts of the container are made of acid-resistant resins and elastomers.

This material is not affected by acidic chemicals, which are difficult to handle.

[characteristic 2] Spraying time

The spraying time for chemical etching, pure water rinsing and N2 drying can be set in one-second increments from the setting screen on the touch panel.

[characteristic 3] automatic processing

Up to six of each spraying command can be entered and are automatically processed in a set order.

Recipes can be registered for safe and reproducible use in repetitive etching operations.

[characteristic 4] rotational control

The sample is placed on a dedicated tray and the rotation can be controlled up to 100 rpm.

By rotating the substrate, the atomized chemical or pure water spreads evenly over the substrate surface.

[characteristic 5] touch panel

Controls other than the sample speed setting time can be made via the touch panel.

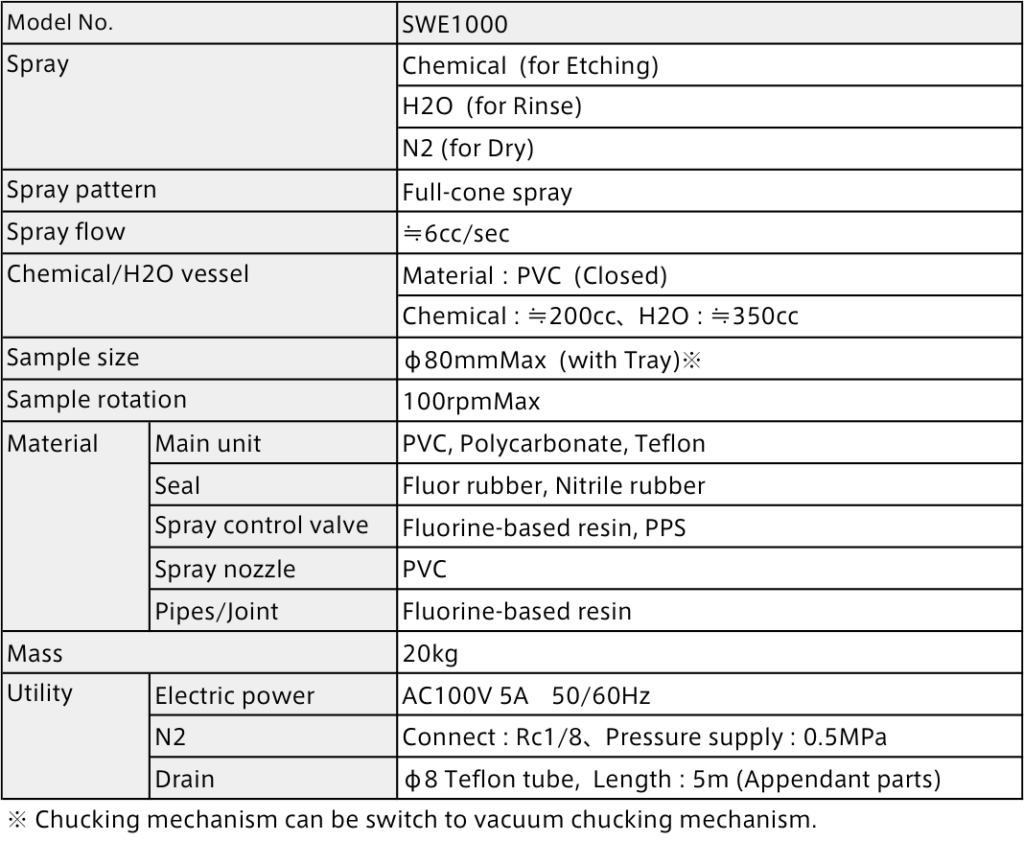

Standard specifications for [SWE1000].

SWE1000 Specification

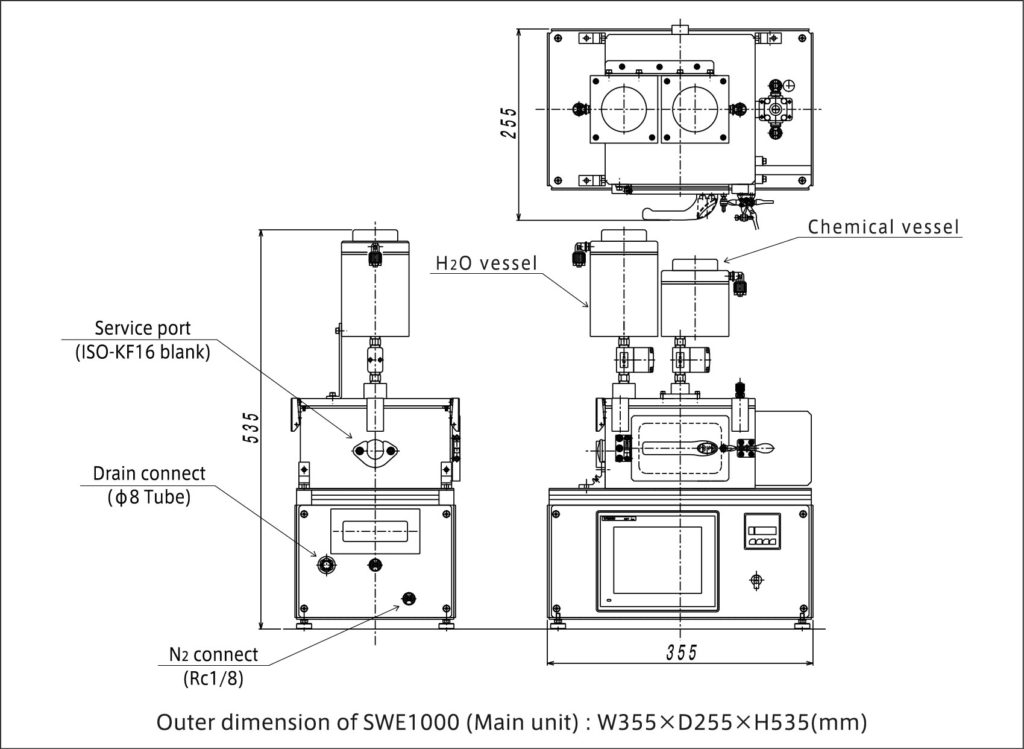

SWE1000 Outer dimension

Repair and modification of [SWE1000].

During the warranty period after delivery of the equipment, we will repair free of charge any initial defects that are not included in certain conditions (malfunctions caused by natural disasters or incorrect usage, etc.) specified by us.

・Periodical maintenance and service response in case of malfunction

・Remodeling or adding functions to equipment and modification of the program software associated with such work

・Relocation of equipment and layout changes

・Operational training (e.g. when the person in charge of operations is replaced)

・Purchase of consumables

・Questions to be answered by email, telephone, etc.