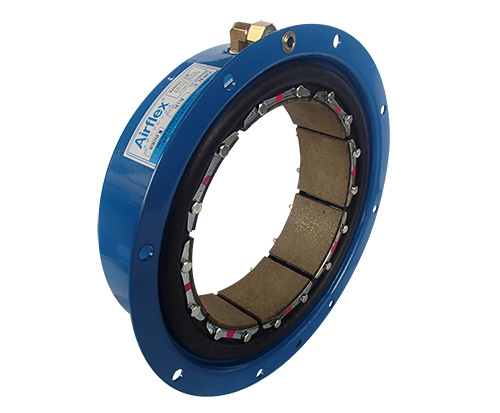

Air ClutchIt is mainly used for the spindle front drive and transmit the engine rotation power to the generator.

Air Clutch

The element for the air clutch is used for the transmission and the block of power generated by the engine.

Friction power is controlled by the expansion and compression of the air tube.

The engine rotation power is transmitted as a driven power of the generator and the hydraulic pump, etc.

Product Information

A little allowance of the shaft can be accommodated due to the elastic tube.

It is also effective for heat dissipation due to the opening structure.

The remote control can be easily done and results in the energy saving.

The mounting and the maintenance are easy due to a small number

of components.

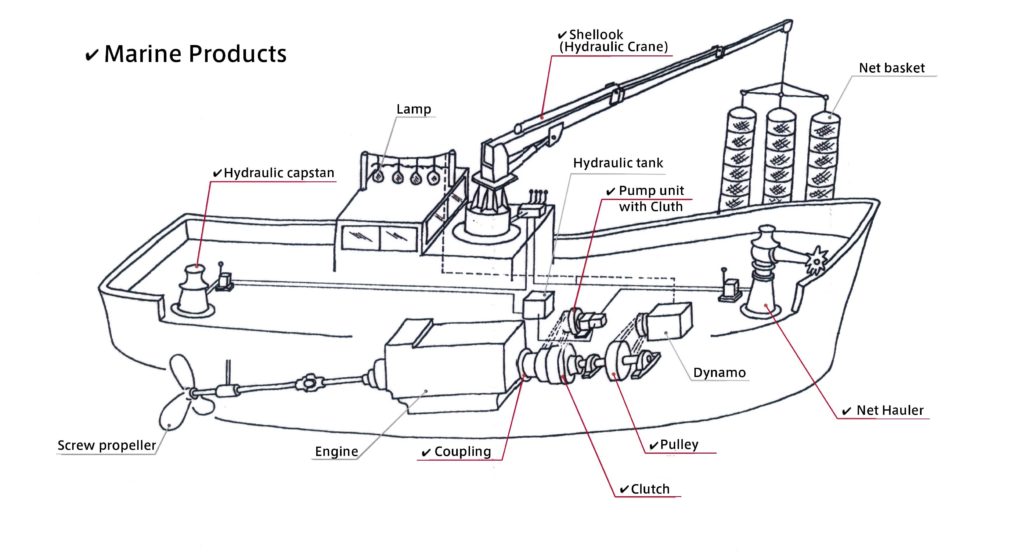

SUGA’s Marine Products (✔️)

SUGA’s Marine Products (✔️)

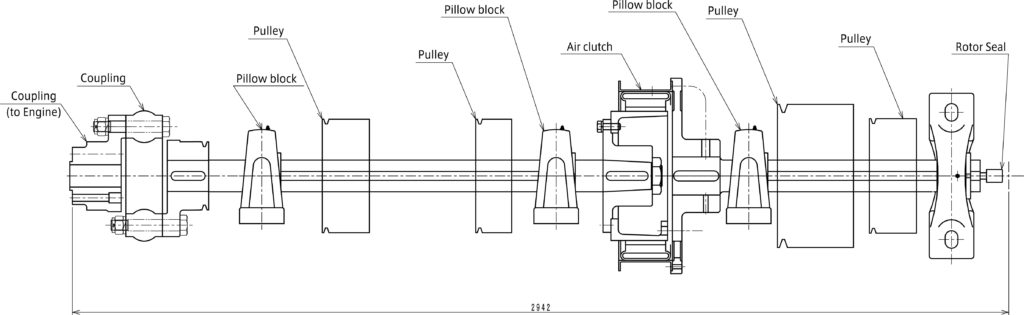

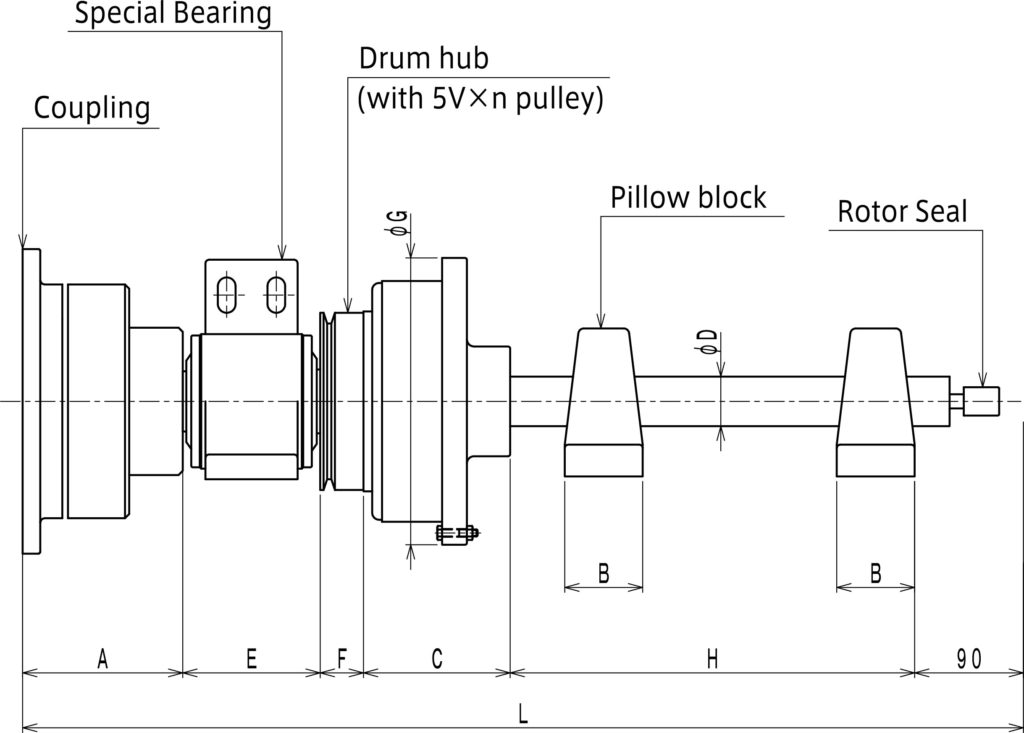

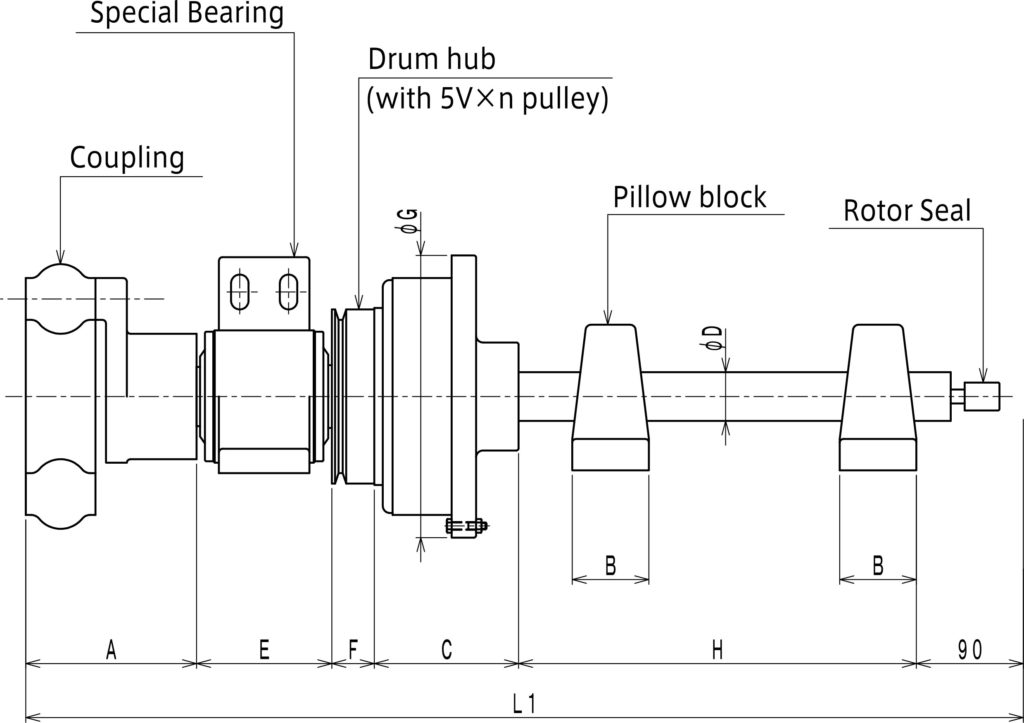

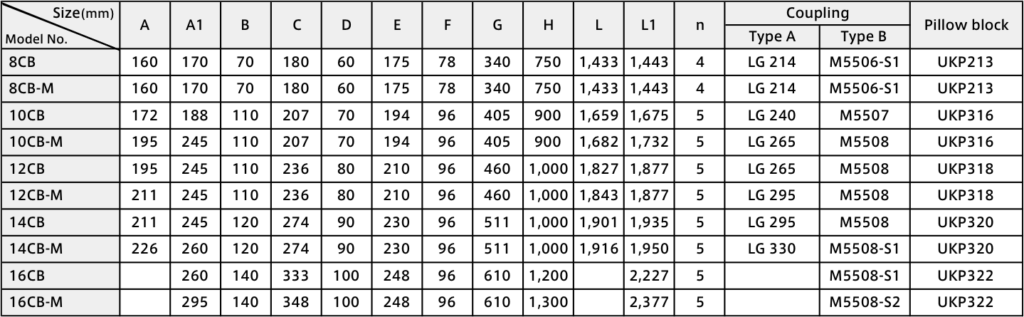

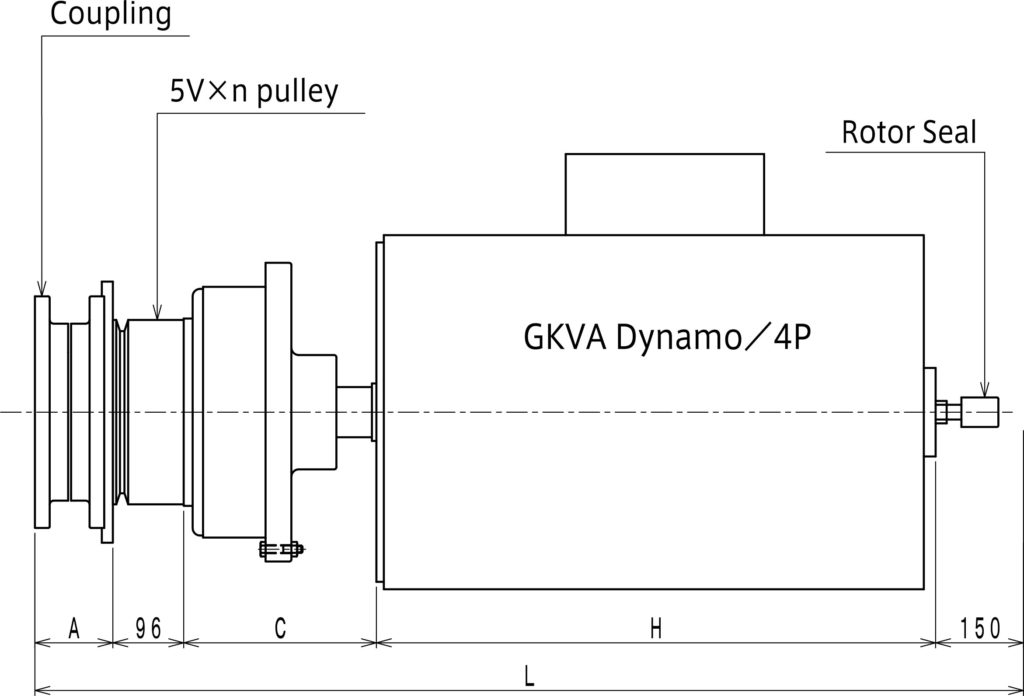

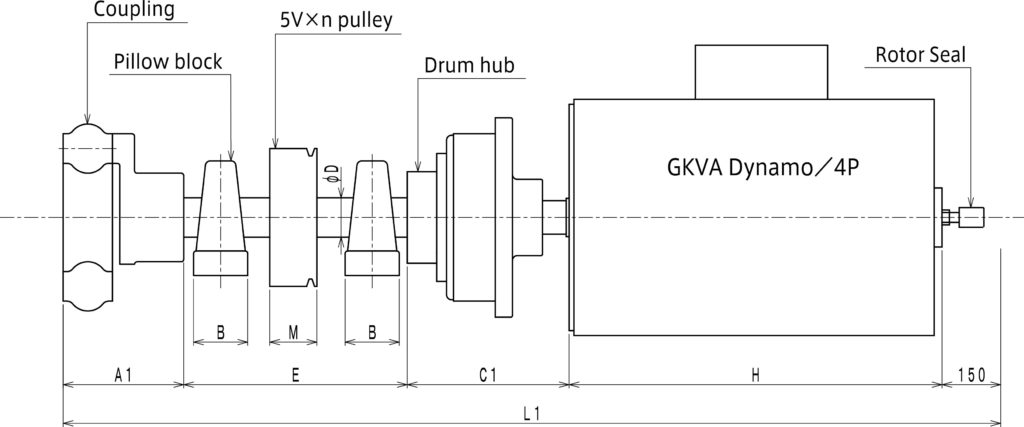

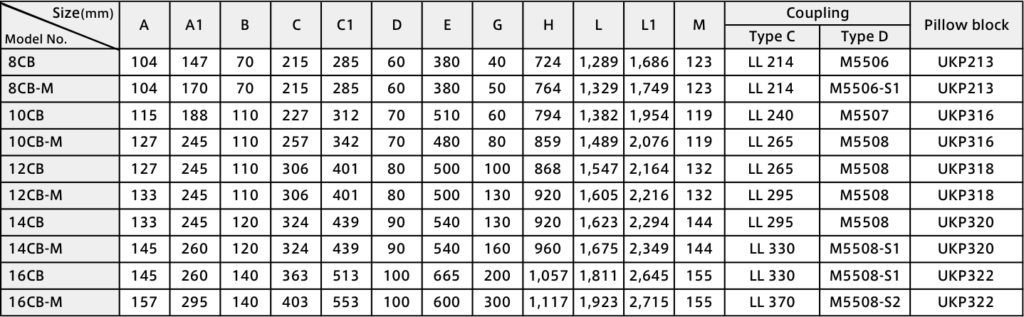

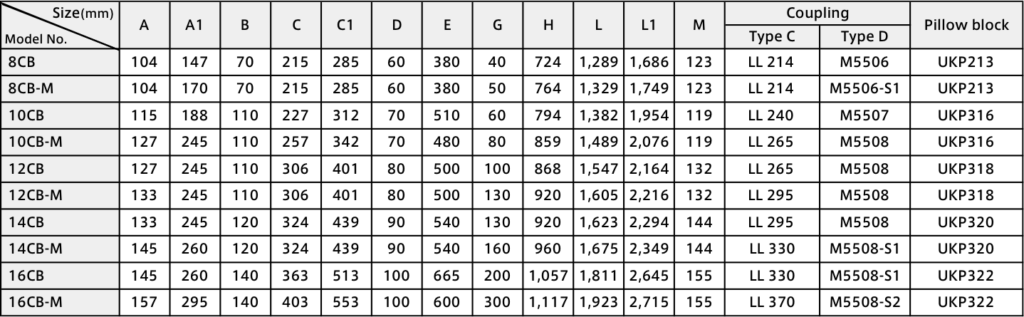

We fabricate spindle front drives as shown in the following figure and the element for the air clutch is used.

The power is transmitted from the engine placed at the left in the figure to the shaft. The power from the engine is transmitted by activating the element when driving the shaft at the right in the figure.

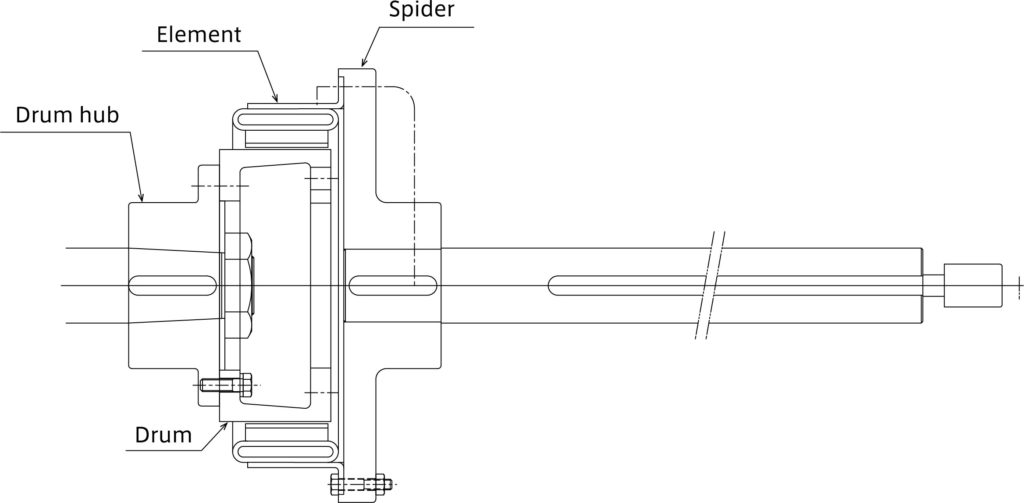

The air clutch is composed of the drum and the spider in response to the element.

Spindle front drive

Component of Air Clutch

Type A,B

Type A

Type B

Type A,B

Type C,D

Type C

Type D

Type C,D

Select Clutch

I Major Calculation formula of clutch and brake

-

Calculation of a torque

- T=9550・P/n=7017・PS/n

-

Calculation of the average kinetic friction torque

- 1) n the case of no load torque

Td=J・n/9.55tae - 2) In the case of the load torque

Start acceleration Td=(J・n/9.55tae)+Tl

Deceleration stop Td= (J・n/9.55tab)-Tl

- 1) n the case of no load torque

-

Calculation of operate time

- 1) n the case of no load torque.

tae=tab=2π・J・n/60Td=J・n/9.55Td - 2) In the case of the load torque

Start acceleration tae=2π・J・n/60(Td-Tl)=J・n/9.55(Td-Tl)

Deceleration stop tab=2π・J・n/60(Td+Tl)=J・n/9.55(Td+Tl)

- 1) n the case of no load torque.

-

Calculation of work

- 1) In the case of no load torque.

Ee=Eb=J・n2/182 - 2) In the case of the load torque

Start acceleration Ee=(J・n2/182)・(Td/Td-Tl)

Deceleration stop Eb=(J・n2/182)・(Td/Td+Tl)

- 1) In the case of no load torque.

-

Calculation of the power

- 1) when there is no load torque.

Pe=Pb=(J・n2/182)・(Nc/60) - 2) In the case of the load torque

Start acceleration Pe=(J・n2/182)・(Td/Td-Tl)・(Nc/60)

Deceleration stop Pb=(J・n2/182)・(Td/Td+Tl)・(Nc/60)

- 1) when there is no load torque.

-

Calculation of a life span

- L=V/w・Ee(orEb)=Et/ Ee(orEb)

The symbol explanation

The T: torque (Nm)

P: motor output (kW)

PS: motor output (HP or hp)

The number of rotations of the

n: clutch brake shaft (r/min)

The kinetic friction torque of the

Td: Dynamic Friction Torque of clutch・brake (Nm)

J: course, the total of the moment of inertia (Kcm2)

Tae: The actual connection hour of the clutch (s)

Tab: Active braking time

Tl: load torque (Nm)

Ee: Clutch connection work(J)

Eb: Braking work of brake(J)

Pe: The connection power of the clutch (W)

Pb: The braking work rate of the brake (W)

Nc: The operation frequency of the clutch・brake (time /min)

L: The connection (braking) number of times until the life (the time)

V: The general volume to the friction plate wear limit (cm3)

w: wear rate (cm3/J)

Et: Total work to the wear limit (J)

Ⅱ Calculation Formula of the coupling torque.

-

The rated torque

- T=9550・P/n=7017・PS/n

-

Design torque

- TD=T・K

The symbol explanation

T: rated torque (Nm)

TD: design torque (Nm)

P: motor output (kW)

PS: motor output (HP or hp)

n: The rotation number of the coupling (r/min)

K: service factor

MAINTENANCE

Spindle front drive