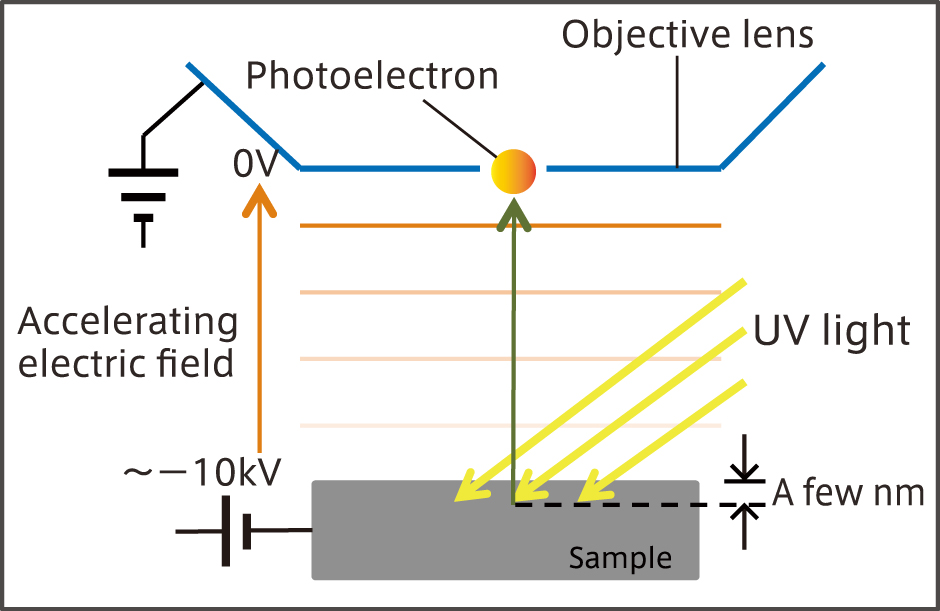

Photo Emission Electron Microscopy (MyPEEM) can visualize the work function of a sample surface in real time by exposing it to short-wavelength light, such as UV light, and detecting the photoelectrons emitted from the sample.

Its main applications include tracking the growth process of thin films and the dynamic process of catalytic reactions.

It can be applied to dynamic observation of the electronic state of the sample surface as it changes due to gas adsorption and desorption, and spin observation using circularly polarized UV light.

Contents

Overview of MyPEEM.

In this system, photoelectrons (secondary electrons) excited by irradiating the sample with UV light are accelerated by a negative high voltage applied to the sample.

The PEEM image is then projected onto a screen using a three-stage electrostatic lens system and a two-stage corrective lens system, and recorded by a CCD camera or other means.

PEEM images can be easily acquired by simply adjusting the height of the sample to match the pre-set field of view in the software.

The chamber, which is the photoelectron pathway, can be placed at ground potential by applying a voltage to the sample, making it safe and compact.

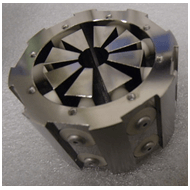

Electrostatic lens system

The system consists of a three-stage lens system.

Each three-stage lens system consists of a four-pole objective lens, a three-pole intermediate lens and a five-pole projection lens.

The desired magnification and field of view are obtained by manipulating the variable electrodes with two, one or two poles respectively, by means of the power supply operation software.

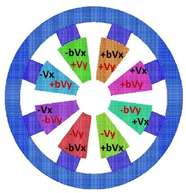

Electrostatic compensator

To compensate for aberrations caused by the lens and assembly, the system is equipped with a two-stage electrostatic compensator developed in-house.

By applying a voltage multiplied by a correction factor to each electrode, optical axis correction and non-point correction can be performed simultaneously using a two-stage compensator.

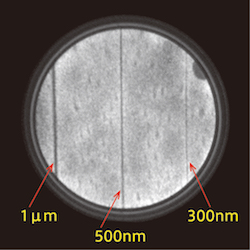

Spatial resolution

The spatial resolution of the device.

Characteristics of MyPEEM.

[Characteristic 1] Stand-alone type

This product is fully operational even without any options as the PEEM main body, chamber, power supply box and control software are all integrated.

[Characteristic 2] Replacement of the light source

The UV light source is used as the excitation light source and is irradiated from outside the vacuum through the viewport, making it easy to replace various light sources.

[Characteristic 3] Manual selection

Three contrast apertures with different hole systems can be selected manually.

[Characteristic 4] Originality

Custom-made sample holders can be produced on request in addition to standard sample holders.

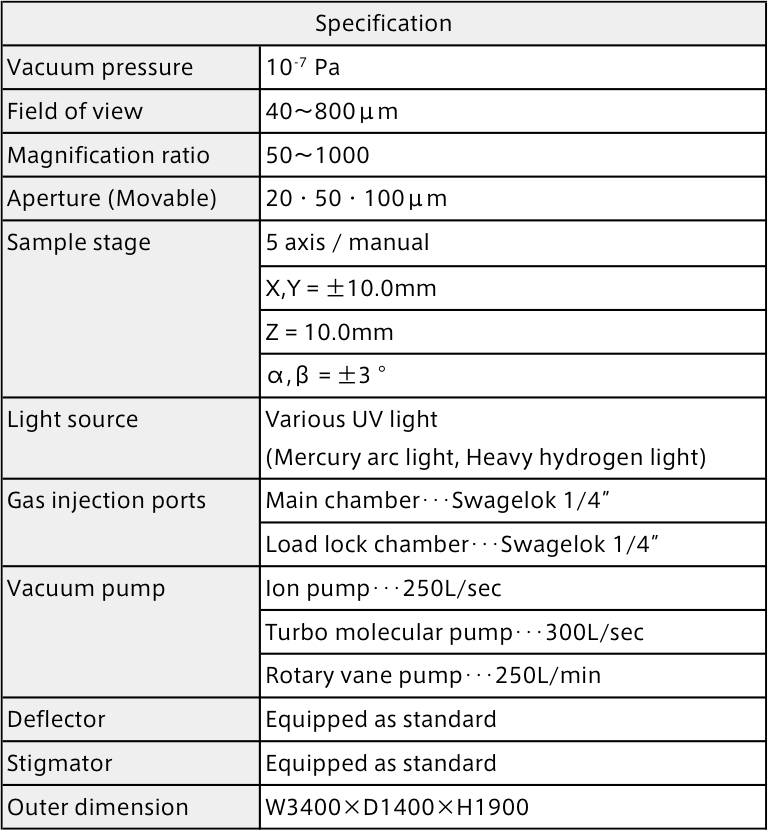

Standard specifications of MyPEEM.

Standard specifications for MyPEEM

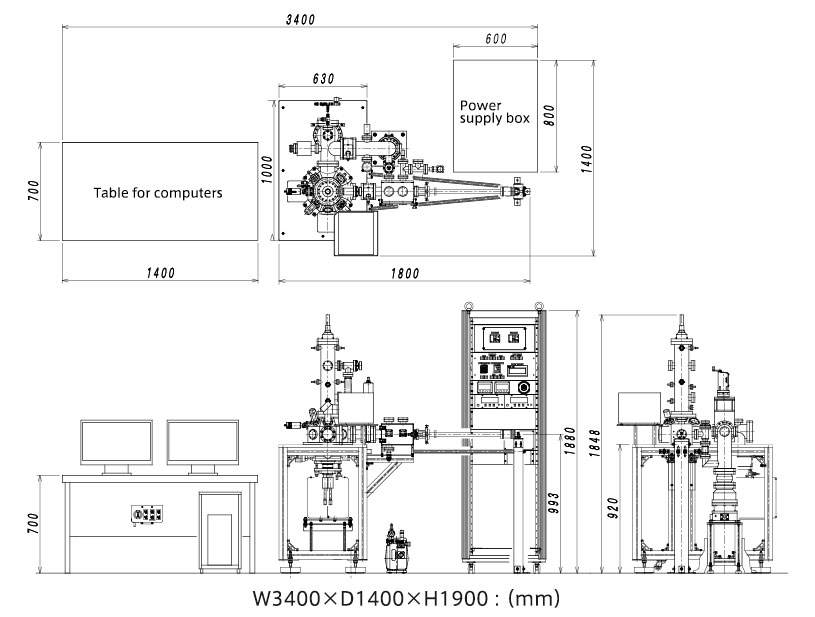

External view of MyPEEM

Repair, modification and maintenance of MyPEEM.

Within the stipulated warranty period after delivery of the equipment, we will repair free of charge any initial defects or other faults that are not covered by certain conditions stipulated by us (failure due to natural disasters or improper use).

- Routine maintenance of equipment and service response in case of malfunction

- Remodeling or adding functions to equipment and modification of the program software associated with such work

- Relocation of equipment and layout changes

- Operational training (e.g. when the person in charge of operations is replaced)

- Purchase of consumables

- Questions to be resolved by email, telephone, etc.