Powder ALDThis equipment is the system suitable for laboratory use to realize the precise step coverage deposition for uniform coating of each atomic layers.

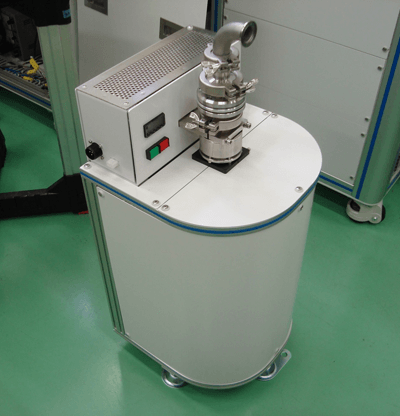

SAL1000B

This model is capable of depositing all over the surface for both powder and solid particles.

POINT

- Deposition of powder by slant + rotation + vibration

- Slant angle ranging from 0 to 45°

- Deposition up to 4 inch substrate

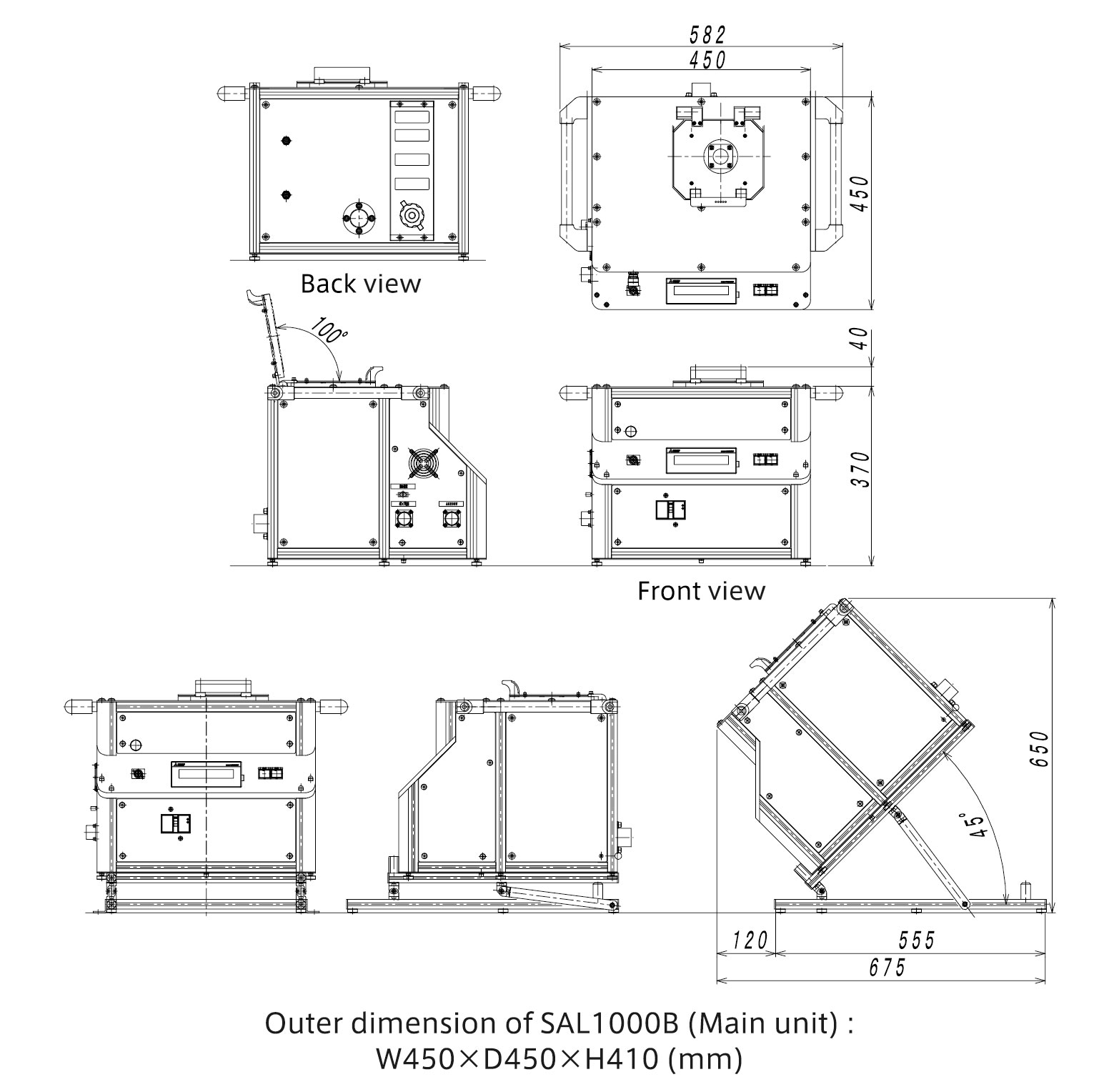

Outer dimension (Main unit)

W582mm×D450mm×H410mm

| Precursor | Uniformity | Substrate heater | Combination |

|---|---|---|---|

| 2 lines | ≦±3% | 350℃ | × |

Outline・Application

This model was developed for R&D.

This equipment is the system suitable for laboratory use to realize the precise step coverage deposition for uniform coating of each atomic layers.

Two precursors can be used with this model for a development of new materials.

The sample film kinds stipulated herein are just for the reference purpose only.

Features

【Features1】Deposition distribution with higher quality

Deposition performance is ≦±3% within Φ100mmarea.

The pin hole free layer deposition can be evenly performed for each atomics on the substrate surface.

The deposition for uneven surface or 3D shape can be suitable due to its step coverage.

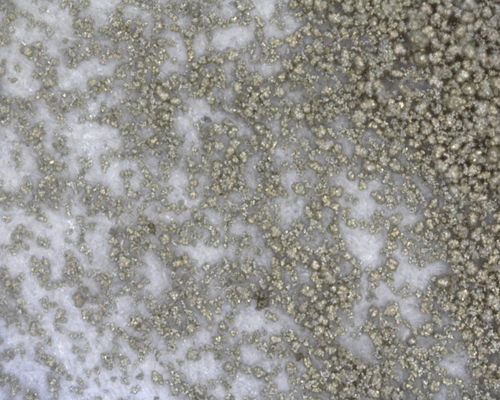

[Before]

Al2O3 deposition on Ni powders (40μm)

(Optical microscope image)

[After]

Al2O3 deposition on Ni powders (40μm)

(Optical microscope image)

【Features2】Easy operation

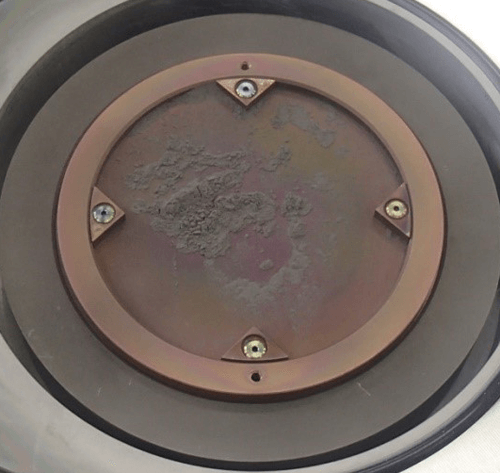

The substrate can be easily placed by lifting up the hatch at the upper side of the system on the substrate holder.

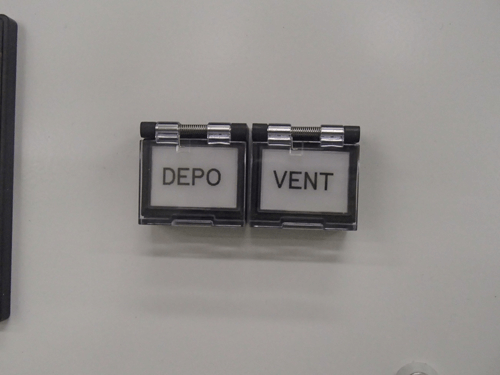

Operation buttons for exhaust and valves for gas flow adjustment are placed on the front panel.

<!–

ハッチを外した状態

–>

Operation button for Depo and Vent

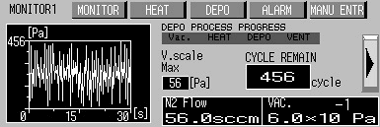

【Features3】Easy software operation even on a small display

The screen layout has been designed so that the deposition status can be easily recognized. Pressure trend graph, Pressure, No.of deposition cycle, remaining No. of deposition cycle, Gas flow and Heater temperature can be read. Other items needed for a system operation and maintenance can be easily read as well.

【Feature4】 Inclinable frame

A frame can be inclined from 0 to 45°to make an effective deposition of powder.

|

|

|

| 0°(Horizontality) | 25° | 40° |

【Features5】Portable Design

A big handle is attached on the side of the system to easily move from the installation place to another place. It weights 50kg and it should be moved by more than two persons.

Promotion Video

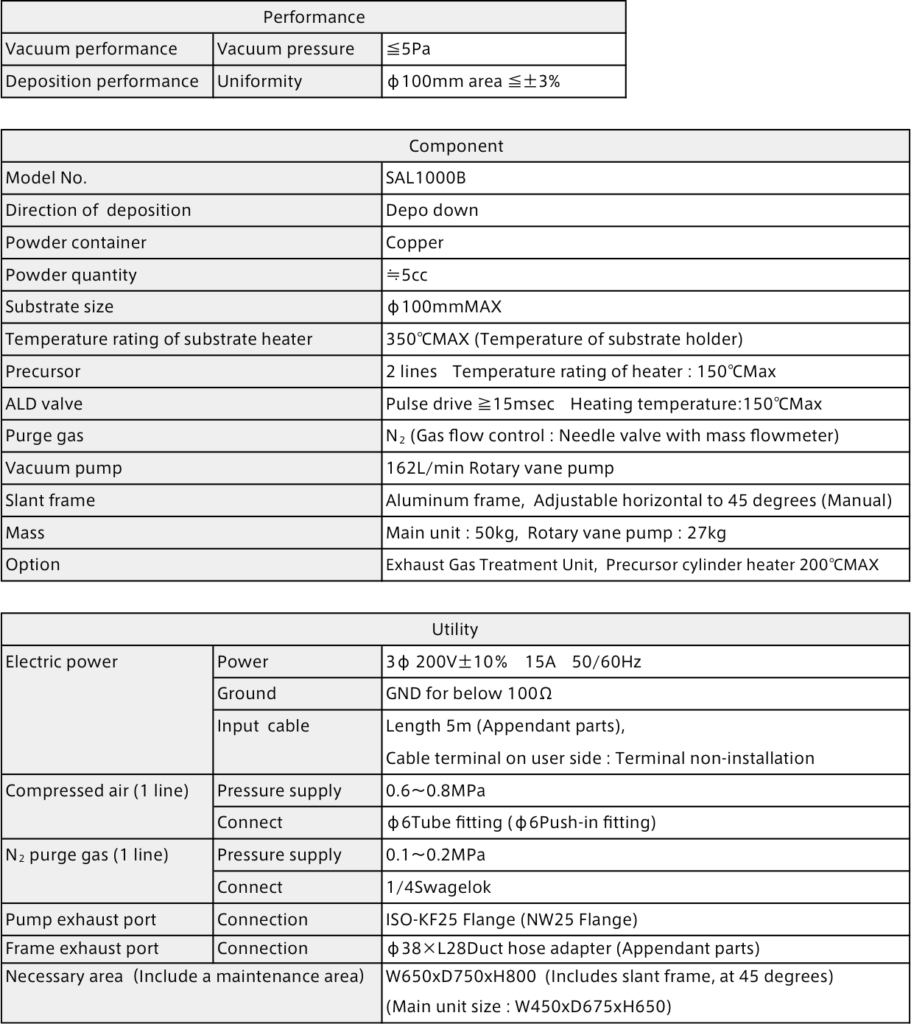

SAL1000B Specification

SAL1000B Outer dimension

Options

The following optional items are available.

【Feature1】Substrate Rotation Mechanism

Substrate Rotation Mechanism can be installed.

【Feature2】Ozone Generator

This generator can be used instead of H2O to make Oxygen atoms react to make a thin film. The vacuum time can be reduced without H2O and the deposition can be made at the low temperature as well.

【Feature3】Exhaust Gas Treatment Unit

The precursor gas exhausted by ALD can be decomposed at high temperature heating. The effect can be obtained if the flow is within a range.

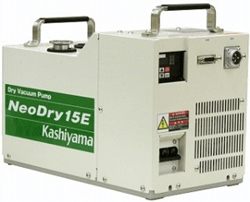

【Feature4】Dry Vacuum Pump

The rotary pump can be replaced with Dry pump.

The dry pump is basically required if a system is installed in a clean room.

N2 gas introduction is recommended for a long life of a system, depending on process conditions.

【Feature5】Heater for Precursor

The jacket heater for precursors (Standard Max. 150℃) is available to maintain steady vaporization of a precursor within a bottle. The jacket heater for precursor (Max.200℃) is available as well.

A thermocouple can control the heater setting temperature and actual temperature of precursor on the operation panel.