Annealing system (Expandable type)This model enables the film to be reformed by the heat treatment of a wafer in a vacuum.

SAN2000Plus

The high temperature heat treatment to substrates (Anneal) and the heat treatment by reactant gas introduction are possible

POINT

- The heating control function from 200℃ to 1000℃ is loaded.

- Plasma treatment can be possible by a model with RF power source.

- The combination with Sputter or ALD systems is possible.

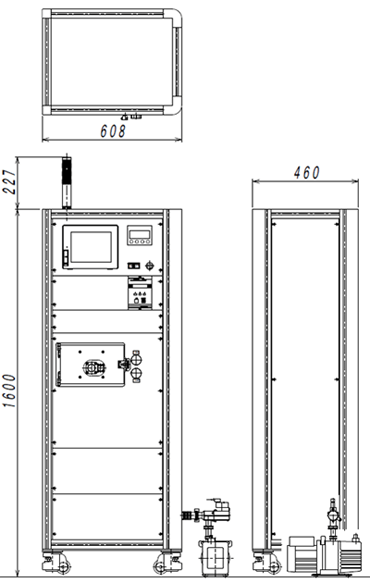

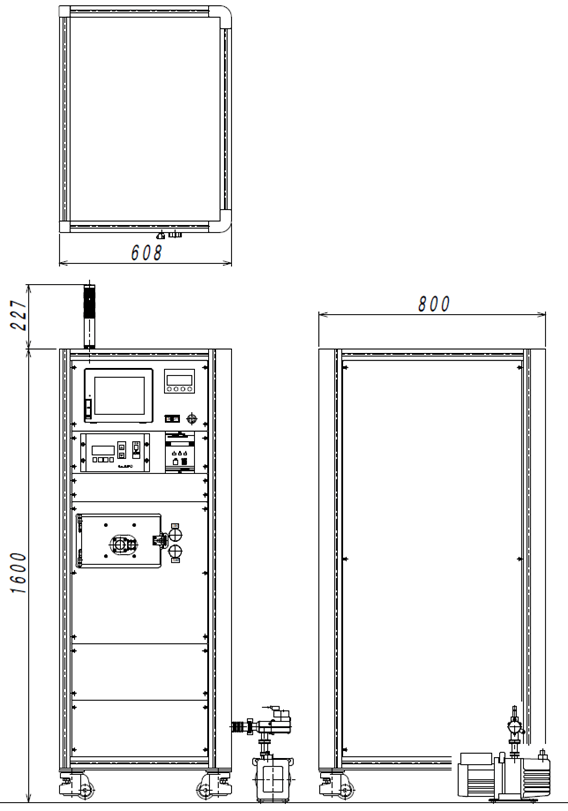

Outer dimension (Main unit)

W608mm×D460mm×H1827mm

| Heating control | Vacuum pressure | Plasma treatment | Combination |

|---|---|---|---|

| 200℃〜1000℃ | 10^-5 | Applicable | ✔ |

Outline・Application

SAN2000Plus is the annealing system which can carry out the heat processing by applying a strong infrared radiation onto substrate up to 4 inches in a vacuum or in a clean environment within a vacuum gas atmosphere.

Feature

【Feature1】Heat treatment method

Heat treatment is possible within a chamber in a high vacuum using turbo molecular pump and it can be done in various vacuum gas atmosphere

with max. 3 units of mass flow controller.

【Feature2】Diversity

For the heating control and cooling time from 200℃ to Max.1000℃, Max.19 steps programs and 30 recipes can be made. Note that the temperature of an actual substrate can be lower than the controlled temperature (Monitor Temperature)

【Feature3】Even Heat Treatment

The heat treatment is possible evenly within ±1.5% for the heat distribution at 800℃ on 4 inch substrate .

【Feature4】High Speed Cooling

Water cooled cold wall structure and substrate cooling gas mechanism realize the high speed cooling.

【Feature5】Plasma Surface Processing Equipment

The substrate surface cleaning and the surface reform are possible as a plasma surface treatment system as well as the heat treatment since an annealing system and RF power source are equipped with this model.

【Feature6】Expandability

The combination with ALD or Sputtering equipment can prevent substrates from an exposure to the atmosphere by adding STR2000 after the purchase.

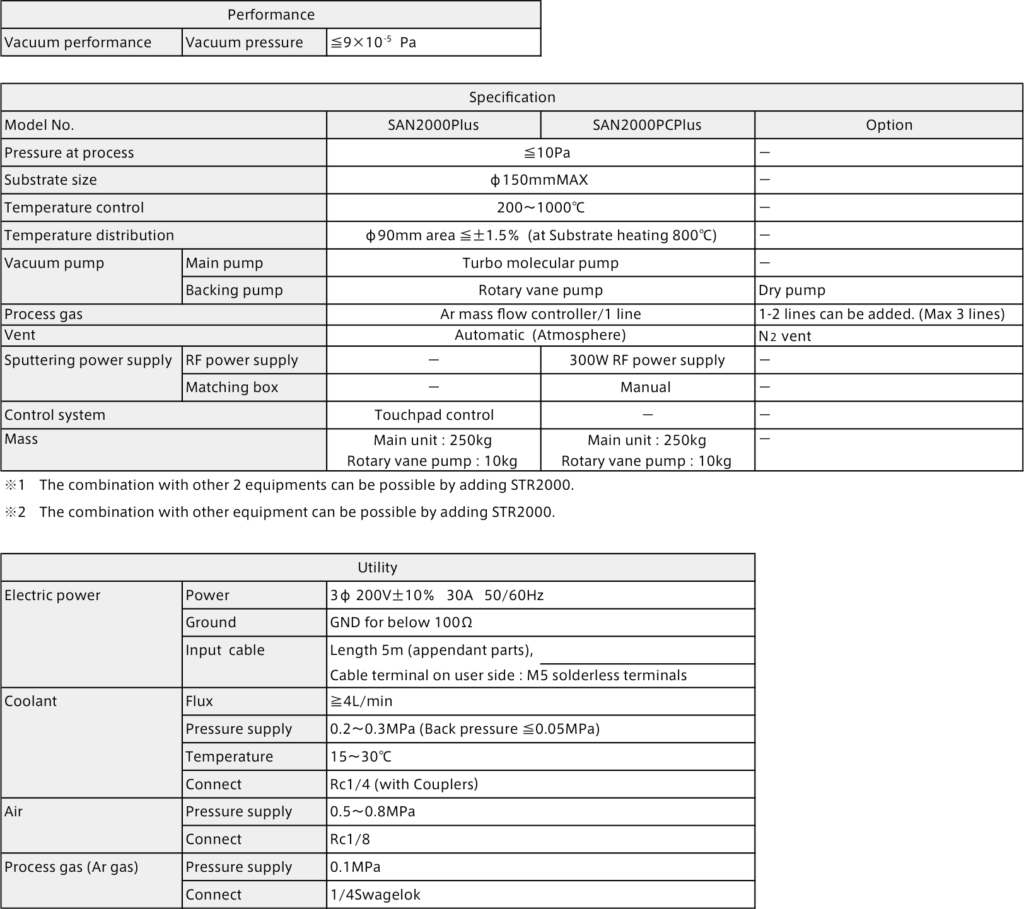

Performance

【Feature1】Better Temperature Control

A better temperature control is possible using the optimized PID algorism.

【Feature2】Program Pattern

Max.19 steps programs per pattern can be made.

【Feature3】Substrate Surface Cleaning

The film adhesion is enhanced by removing a naïve oxide film and contamination.

【Feature4】Substrate Surface Interfacial Activity Treatment

The surface activity treatment for hydrophilia, etc. is possible.

【Feature5】Better operability

The operation of Exhaust and gas introduction, Heating program control and recipe setting can be done by a touch screen.

【Feature6】High Level of Safety

A whole chamber is water cooled and various interlocks for vacuum exhaust, heating, cooling water amount and high frequency protection, etc. are equipped with this model.

SAN2000Plus Specification

SAN2000Plus Outer dimension

SAN2000Plus

SAN2000PC-Plus