Sputtering equipment is a deposition system that uses the sputtering phenomenon, in which Ar ions collide with a target under the condition of plasma discharge and the target material knocked out by the collision adheres to the opposing substrate.

There are several types of sputtering systems that use different methods.

This article introduces five typical methods.

Contents

- 1 Introduction of principle of RF (radio frequency) sputtering, which can also be used for electrodeless inductive discharge.

- 2 Introduction of principle of magnetron sputtering, which can increase sputtering speed.

- 3 Introduction to the principle of the bipolar sputtering, which is the original form of deposition technology.

- 4 Introduction to the principle of the opposed target method of suppressing which controls collisions on the sample surface

- 5 Introduction to the principles of ion beams, which enable the formation of dense films.

- 6 Summary

Introduction of principle of RF (radio frequency) sputtering, which can also be used for electrodeless inductive discharge.

RF (radio frequency) sputtering can target insulators and sputter them at high frequencies.

Power is supplied to the electrodes from the high-frequency power supply.

Positive and negative ions are swept to the target side by the high frequencies as the plasma is generated.

The target side is negatively biased and insulators are sputtered as a result of cations impinging on them.

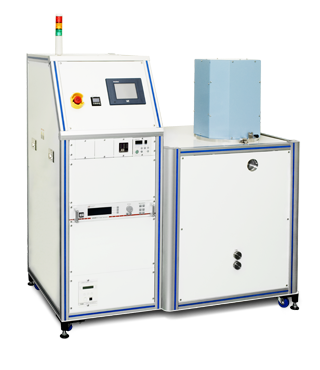

SSP1000 (Cubic sputtering equipment).

Entry model of SUGA’s desktop RF sputtering system.

- Despite being a desktop model,Φ100 mm film thickness distribution ±5% max. is possible.

- Three functions in one unit, with a choice of deposition direction depending on the purpose.

- Equipment can be set up by the user

For more information on SSP1000

Introduction of principle of magnetron sputtering, which can increase sputtering speed.

This method reduces the effects of plasma in DC sputtering and increases the sputtering speed.

Plasma is generated in a vacuum, and it is the unstable condition because positive and negative electrons are free to fly around.

Those ions then collide with the densely captured targets one after the other.

This method enables efficient sputtering, as the magnetic force generates plasma with less power.

SSP3000 (sputtering equipment)

High-end model of sputtering equipment with high performance and a variety of options.

Equipped with three 2-inch diameter magnetron cathodes (with shutters).

- High-performance models with ternary cathodes

- Film thickness distribution within ø 100 mm ±3% or less

- L/L rooms can be installed without changing the external dimensions.

For more information on SSP3000

Introduction to the principle of the bipolar sputtering, which is the original form of deposition technology.

The bipolar sputtering method is considered as the original form of deposition technology.

A voltage is applied to the target and sample, and the particles produced by impacting the target are deposited on the sample to form a film.

The structure of the device is simple, but there are problems with the negative ions flowing into the positive electrode, which results in high temperatures and significant damage to the sample.

Tri-polar or quadrupolar DC sputtering facilitates the maintenance of the discharge by irradiating the gas with thermal electrons emitted from the thermal filament, and the discharge voltage is reduced to 2 kV or lower, resulting in better film quality than dipolar sputtering.

Introduction to the principle of the opposed target method of suppressing which controls collisions on the sample surface

Two targets are placed opposite each other and the sample is placed beside them to suppress the collision of energetic particles with the sample surface, which is a disadvantage of the magnetron sputtering method.

Permanent magnets installed behind the two opposing targets create a magnetic field structure that surrounds the target with a magnetic flux.

This permanent magnet causes the magnetic flux and negative voltage electrons to move back and forth between opposing targets.

This behavior causes it to collide with the gas, forming a dense plasma.

The magnetic field formed between the opposing targets restrains the plasma here, resulting in suppression of the plasma’s effect on the substrate surface and enabling low-temperature deposition.

Introduction to the principles of ion beams, which enable the formation of dense films.

Ion beam sputtering equipment can form dense films in a high vacuum.

A wide range of targets can be adapted, including metals and magnetic oxides.

Due to the large number of target applications, there is a wide range of uses.

It can be used for laminated films of magnetic and non-magnetic materials, dielectric laminations, etc.

There is also a dual ion beam deposition system.

This equipment is ideal for X-ray mirrors and coatings for gradient shapes, and can be used from research and development to mass production.

Summary

In this article, the typical methods and principles of sputtering equipment have been explained.

We manufacture vacuum equipment and provides vacuum and piping components required to configure vacuum equipment and vacuum facilities, such as annealing equipment for film quality improvement applications after film deposition as vacuum equipment.

We also offer support for test servicing, repairs and modifications, so please contact us.