Contents

‘CVD (chemical vapor deposition)’.

There are several types of thin film formation, as shown in the diagram below.

How to make thin films | Details |

|---|---|

evaporation method | This technique forms thin films by evaporating deposition materials such as metals and oxides in a vacuumed container and depositing them on the surfaces of opposing substrates. References※1.2.3.4 |

Ion plating (IP) method | In principle, it is almost identical to the evaporation method, but the evaporation material is ionized by passing the evaporation particles through a plasma. A negative voltage is applied to the substrate to be deposited and the ionized deposition material is accelerated to impact the substrate to form a thin film. Ionization and acceleration can create highly adherent films. References※1.5 |

sputtering method | Ions (usually Ar+ ions) created in the plasma by the discharge strike a plate (target) of the deposition material, which splashes the material. This is a method whereby the flung deposition material flies to the substrate to form a thin film. The sputtering method can be used for a wide range of deposition materials, such as metals and alloys with high melting points, which are difficult to deposit using the vapor deposition method. References※1.5.6 |

| Chemical vapor deposition (CVD) method | A method whereby gases containing the elements to be deposited are pumped onto the surface of a substrate and the films are deposited through chemical reactions and decomposition. There are different types of CVD, including thermal CVD, where the substrate is heated, and plasma CVD, where the reaction tube is depressurized and plasma is generated. References※1.7.8 |

Atomic layer deposition (ALD) method | Atomic layer deposition (ALD) is also called a type of CVD, in which two or more types of raw material gases (precursor) are alternately introduced and exhausted to form a film by reacting the molecules of the raw materials that are adsorbed on the deposition surface. references※8.9 |

Explanation of chemical vapor deposition (CVD).

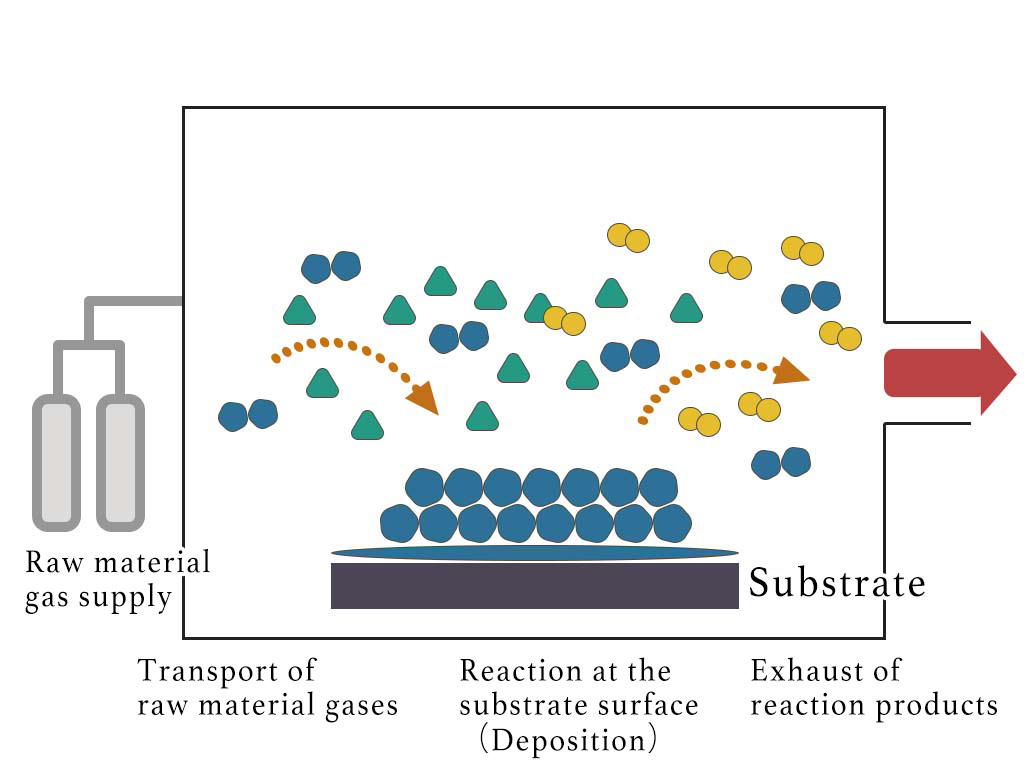

In CVD, the raw materials for the thin film are supplied to the deposition chamber in the form of gas, which is decomposed by heat or plasma energy to form a metallic or compound thin film that is deposited on the surface of the substrate material.

No other thin film fabrication technology is as versatile as CVD.

It’s used in a wide range of applications, such as electronic devices, decorative coatings, hard coatings and film coatings.

Principles of CVD

The principle of CVD is explained in more detail with reference to the diagram above.

- Raw material gas supply

- Transport of raw material gases to the surface of the substrate.

- Diffusion and decomposition of raw material gases at the substrate surface.

- Nucleation and evaporation of volatile reaction products

- Removal of reaction products

The key factors determining film quality in CVD methods are the following.

- What raw gas combination to use?

- How much flow rate of gas would be applicable?

- How much pressure to use?

- How much energy does it take to decompose the raw material gas and grow thin films?

Introduction of three types of CVD methods.

CVD is classified according to the method of decomposition of the raw material gas as follows.

1.thermal CVD

Thermal CVD involves the heat to decompose the raw material gases.

The temperature of the substrate is the temperature required for the dissociation of the raw material gas.

Fairly high temperatures of 500-700°C when depositing metal thin films and 700-1000°C when depositing metal nitride and carbide thin films.

Therefore, if the substrate is not heat resistant, the thermal CVD cannot be used.

2.plasma CVD

Plasma CVD uses plasma to decompose the raw material gas. Substrate temperatures can be lower than it’s required for thermal CVD.

It is not practical for substrates with large areas due to the difficulty in obtaining uniform film pressure and quality.

3.MOCVD

MOCVD is a special CVD method that uses organometallic compounds as the raw material gas.

Organometallic compounds are compounds formed by the association of metals with hydrocarbon groups.

Devices fabricated by MOCVD are used in a surprisingly large number of applications.

Infrared light-emitting diodes are used as light sources for household appliance remote controls, while light-emitting diodes for blue light are used for traffic signals.

It’s also heavily used in the process of creating semiconductor lasers, and laser diodes are used to read signals on CDs and DVDs.

Furthermore, listening to music and watching DVDs are also possible thanks to this technology.

Summary

When forming thin films, different methods and equipment are used, depending on the application and material.

In this article, the CVD (chemical vapor deposition) method, a thin film formation process, was explained.

We manufacture and supply R&D equipment, which is indispensable for deposition.