There are many methods of sputtering, of which ‘magnetron sputtering’ is introduced today.

The principles of magnetron sputtering, easy-to-understand illustrations, and the advantages and disadvantages during deposition are also explained.

Contents

Principle of magnetron sputtering

Magnetron sputtering was developed to improve the slow deposition rate of bipolar sputtering.

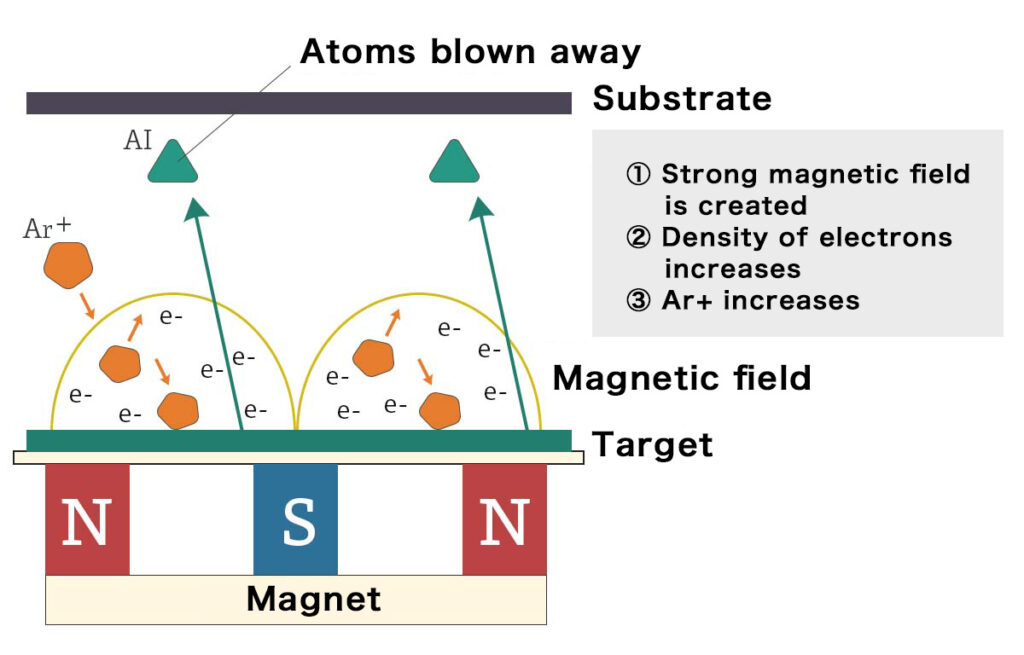

By enclosing electrons in a magnetic field using magnets, a dense plasma region is created, increasing the probability of argon atoms striking the target and thus increasing the speed at which they adhere to the substrate.

Magnetron sputtering is now the standard method.

Advantages and disadvantages of magnetron sputtering

Advantages

- The substrate is less damaged by the heat and ions of the plasma.

- Fast and efficient deposition of films

Disadvantages

- The magnetic field is not uniform, so that plasma with a higher concentration is generated in areas with a higher magnetic flux density, the lower the location of magnetic flux density, the lower the concentration of the plasma.

- In the case of magnets, the magnetic flux density is generally lower in the center of the S and N poles, so the plasma is thinner in the center.

- The amount of target removal is likely to be uneven (also called erosion).

Illustration of magnetron spattering.

A permanent magnet is placed below the target and the magnetic field generates a high-density plasma, which is deposited by atoms bounced off the target by sputtering.

Introduction of magnetron sputtering equipment of SUGA

SSP3000

High-end model of sputtering equipment with high performance and a variety of options

Summary

This article explains the principles and features of magnetron sputtering in detail.

In addition to sputtering equipment, we also manufacture other vacuum equipment such as ALD and evaporation equipment.

If you are interested, please click here for a list of products.