Sputtering equipment is widely used for R&D.

Sputtering equipment is a PVD thin film forming system that uses the ‘sputtering phenomenon’, in which Ar gas ionized under a plasma discharge collides with a target at high speed, and the target atoms knocked out by the collision adhere to the opposing substrate.

The problem is that many labs struggle to find space for this equipment.

Therefore, we introduce SUGA’s compact desk model sputtering equipment [Cubic sputtering equipment: SSP1000] .

Many people may be concerned about performance when they find that it is small, but the SSP1000 is not just compact but perform well enough and has been well received by customers including university research institute who is conducting cutting-edge research.

Contents

①SPS1000 can be placed in different ways.

Pattern A

Pattern B

Both stacked (stacked) and parallel (horizontal) arrangements are possible to accommodate a variety of installation environments.

Moreover, the power supply unit and pump can be floor-mounted and only the chamber can be placed on a rack.

If the power supply and chamber are to be separately installed, you are kindly requested to advise us beforehand as cable lengths etc. may be insufficient.

As necessary, optional special stands and other equipment are available on request.

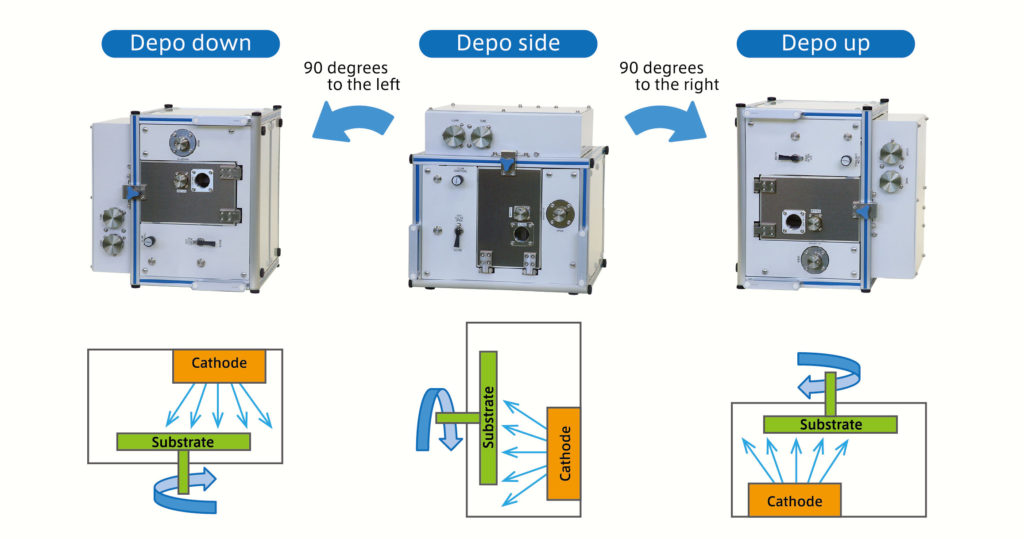

②SSP1000 can freely change the deposition direction.

As the name of cubic sputter indicates, it is possible to change the deposition direction in three directions: sputtering UP, sputtering SIDE, and sputtering DOWN by pulling round the dice-shaped chamber (deposition chamber).

Sputtering UP

Most of the users employ this film deposition direction since this is the best way to prevent the adhesion of the particle to the substrate.

It is excellent in workability during maintenance since the target faces downward.

Sputtering SIDE

This arrangement prevents particles from adhering to the substrate and flakes from adhering to the target which ensures high quality deposition.

The workability on fine-tuning of distance between target and substrate (T/S) is superior among those three ways.

Sputtering DOWN

This deposition direction allows to simply place the sample on a substrate holder, it is useful for deposition of irregularly shaped substrates and small components side by side.

Constant attention is required because particles tend to fall on the substrate side.

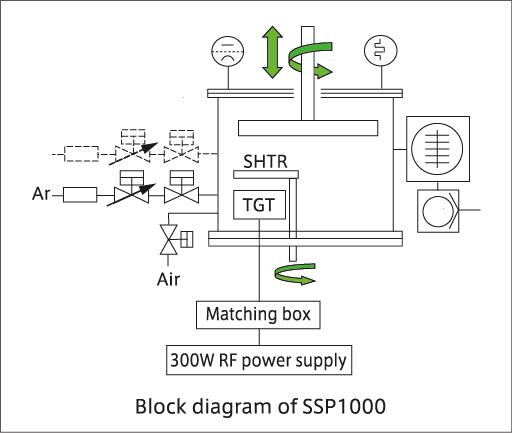

③No compromises even with compact desk model sputtering equipment, SSP1000 adopts the same cathode as the upper model.

It carries φ 2 inches magnetron cathodal one engine (with a shutter) and achieves less than film thickness distribution ±5% within φ 100mm.

We did not compromise but adopted cathode structure same as the upper model even for this entry model.

If magnetic materials are to be deposited, the water-cooled magnet can be removed and replaced with a high-field magnet (to be purchased separately) to be capable for it.

Summary

In this article, the advantages of using SUGA’s compact desktop sputtering system, SSP1000 are presented.

Even with limited space, there is no need to give up on installing sputtering equipment with this SSP1000. High performance is guaranteed although it’s small.

In addition to this SSP1000, a wide variety of other sputtering equipment is also available.

Click here to see other sputtering equipment.