Introduction of Suga’s Shellook hydraulic cranes used on scallop farm vessels, oyster farm vessels, and small stationary vessels.

We, Suga, are engaged in the design, manufacture, and sales of shellac hydraulic cranes all at once.

There are 3 types, Shellook 300, Shellook 500 and Shellook 500A which is widely used in scallop and oyster farming vessels, as well as small stationary vessels.

In particular, the Shellook 300 is smaller than other companies’ products and is used on many small vessels.

Stainless steel parts & corrosion-resistant zinc plating achieves durability.

Contents

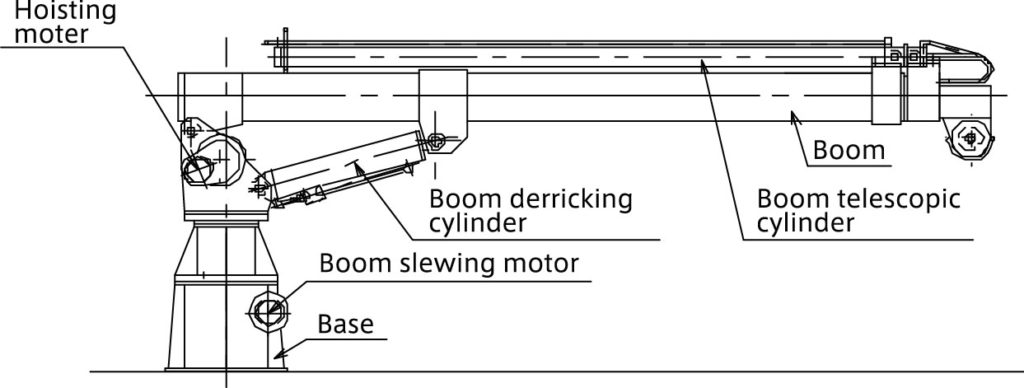

Product information of our Shellook hydraulic cranes.

Shellook hydraulic cranes are developed for marine use

They feature a robust structure to cope with loads that cannot be expected on land due to wave effects.

For additional corrosion resistance, the body is hot-dip galvanized and, as for the cylinder rod, it is either stainless steel rod or double hard chrome-plated.

Three types are available with hoisting capacities of 300 kg and 500 kg, and with automatic or semi-automatic booms, and are widely used on scallop and oyster farming vessels, as well as on small stationary vessels.

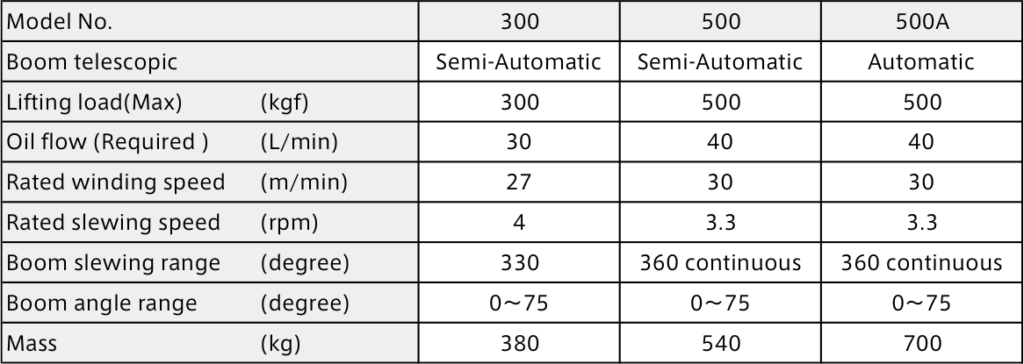

Standard specifications of our Shellook hydraulic cranes

Specification table

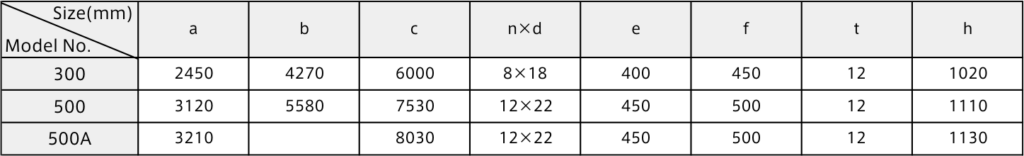

External view of Shellook

※Specially made mounting bases for each model are also available.

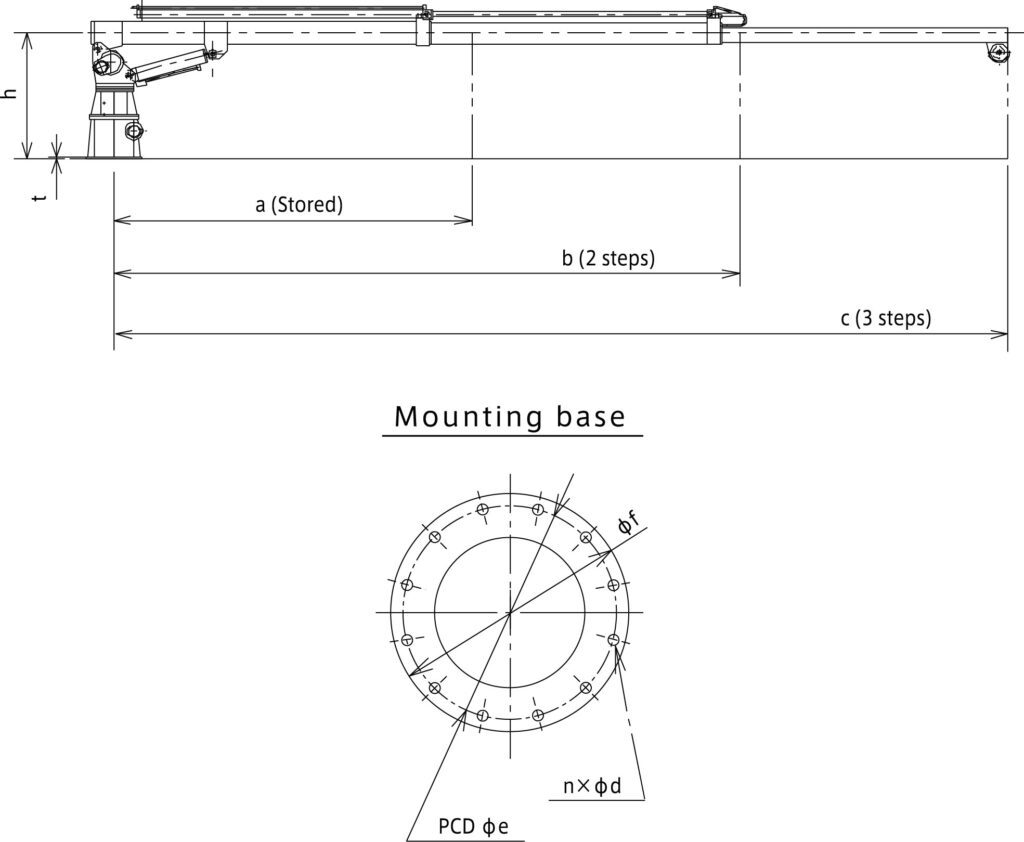

Main formulae for hydraulic equipment

| hydraulic pump | |

| Shaft input of pump | Ls=(P・Q/60η)・102 |

| Oil power of the pump | Lp= P・Q/60=η・Ls・10-2 |

| Total efficiency of pump | η=ηv・ηt・10-2 |

| Volumetric efficiency of the pump | ηv=(Q/Qth)・100≒(Q/Q0)・100 |

| Efficiency of prime mover | ηe= Ls/ Le |

| hydraulic motor | |

| Theoretical push-off volume of hydraulic motors | Dth=(2π・T)/(P・ηt)・102 |

| Output power of hydraulic motors | Ls=2π・T・N/60000=η・(P・Q/60)・102 |

| Input power of hydraulic motors | Lm=P・Q/60 |

| Volumetric efficiency of hydraulic motors | ηv= (Dth・N/Q)・10-1 |

| Torque efficiency of hydraulic motors | ηt= (2π・T/P・Dth )・102 |

|

Total efficiency of hydraulic motors | η=ηv・ηt・102= (Ls/ Lm)・102=(2π・T・N/P・Q)・10-1 |

| Cylinder | |

| Pressure required for cylinder. | P1=(1/ A1)・(F/ηc+P2・A2・102) ・10-2 |

| Required flow rate for cylinder | Q= A1・v・10-1+QL |

| Thrust of the cylinder | ・Acceleration【F1=m・α=m・v1/t】 ・static friction resistance【F2= μs・m・g】 ・dynamic frictional resistance【F3= μd・m・g】 |

Symbol Description

- Shaft input of pumps, output power of prime mover, output power of motor

- Oil power of pumps

- Input power of the prime mover

- Motor input power

- Pump discharge pressure, pressure difference at motor input/output ports

- Pressure required for cylinder.

- Cylinder inlet pressure

- Discharge volume at discharge pressure P, oil flow into the motor and required flow rate of the cylinder.

- Theoretical Dispensing Volume

- Discharge pressure at discharge rate P≒0

- Internal cylinder leakage

- Shaft torque Shaft torque

- number of rotations

- Total pump efficiency, total motor efficiency

- Volumetric efficiency of pumps and motors.

- Torque efficiency of pumps and motors

- Efficiency of prime mover

- Thrust efficiency of cylinders

- Theoretical push-off volume of the motor

- Cylinder inlet side pressure receiving area

- Cylinder outflow side pressure receiving area

- cylinder thrust

- Cylinder acceleration force

- static friction resistance

- dynamic frictional resistance

- Speed of cylinder

- Speed after acceleration

- Mass of load

- rate of acceleration

- acceleration time

- coefficient of static friction

- coefficient of kinetic friction

- Acceleration of gravity

Repair and modification of our shellook hydraulic cranes.

Overhauls and repairs can be performed at our factory.

We also sell parts for undulating cylinders and telescopic cylinders.

Please feel free to contact us.