Vacuum equipment refers to devices that utilize vacuum conditions, and vacuum systems are set up and operated according to the purpose.

It is an indispensable piece of equipment in recent industrial developments and in various applications and research.

Therefore, this issue introduces eight types of vacuum equipment and a total of 17 machines from AGUS, which deals with vacuum equipment.

This is a useful reference for research institutes and those considering it in the development of new materials.

Contents

- 1 Photoemission electron microscopy (PEEM) for real-time 2D mapping of sample surfaces.

- 2 Sputtering equipment for deposition systems using the sputtering phenomenon.

- 3 ALD system capable of depositing films with high film quality and high step coverage.

- 4 Evaporation equipment for depositing films on substrates by evaporating metallic materials installed in a heat source.

- 5 Annealing equipment for high temperature heat treatment to substrates.

- 6 Transfer unit to transport wafers to the equipment under vacuum.

- 7 Heating furnaces with higher precision temperature control.

- 8 Space chambers for space environment testing, etc

- 9 In summary: Leave it to us! if you are in need of vacuum equipment,

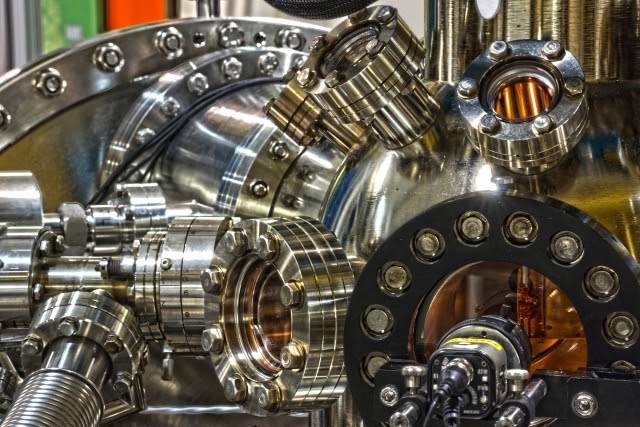

Photoemission electron microscopy (PEEM) for real-time 2D mapping of sample surfaces.

Photoemission electron microscopy is an electron microscope that detects photoelectrons emitted from a sample by exposing it to short wavelengths of light, such as ultraviolet light.

Uses

The main application is to track the dynamic processes of thin film growth and catalytic reactions.

It can also be applied to gas adsorption and spin observation using circularly polarized UV light.

Products

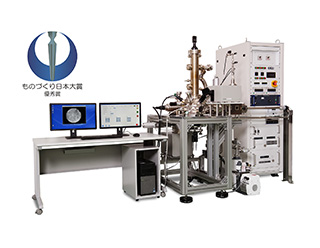

MyPEEM

Japan’s only general-purpose photoemission electron microscope.

To compensate for aberrations caused by the lens and assembly, the system is equipped with a two-stage electrostatic compensator developed in-house.

Sputtering equipment for deposition systems using the sputtering phenomenon.

Sputtering equipment is a PVD thin film forming system that uses the ‘sputtering phenomenon’, in which Ar gas ionised under a plasma discharge collides with a target at high speed, and the target atoms knocked out by the collision adhere to the opposing substrate.

Uses

It can be available in research and development such as a metal film, the insulation film, a transmission film, the insulation film, a protective film, a reflection film, a catalyst, coating, a circuit, a battery, MEMS, the new materials development.

Products

SSP1000 Cubic Sputtering Equipment

Entry-level model for desk top RF sputtering.

Even the table-top model has a performance of less than ±5% Φ100 mm film thickness distribution and uses the same cathode structure as the higher-end models.

The system can be adapted to the installation environment by changing the deposition direction and selecting the placement method.

SSP2000Plus Expandable Sputtering Equipment

A middle model that is easy to use for experiments, this slim tower of 2D cathodes can be combined with ALD and annealing equipment.

When connected to the STR2000, it has the function of a load lock chamber.

More information on SSP2000Plus

SSP2500G Sputtering Equipment with Glove box

Equipped with a simple vacuum-replaceable glove box (made of acrylic resin), which allows substrate replacement and target removal and attachment without exposure to atmospheric moisture or oxygen.

Targets and wafers can be opened in GB.

SSP3000 High-end model Sputtering Equipment

This is a multifunctional, three-dimensional cathode, high-performance model of sputtering equipment.

The design of the touch panel, which takes visibility and operability into consideration, and the design of the deposition chamber, which combines the main unit with the exhaust system and the electrical control system mount into a single unit, enhance the appearance and functionality.

SSP3000Plus High-performance model expandable Sputtering Equipment.

Advanced thin-film manufacturing processes are possible, such as stacking with ALD equipment, which is achieved by linking with Plus series equipment, and combining with annealing equipment for heat treatment and gas displacement treatment.

Expandability

More information on SSP3000pPlus

ALD system capable of depositing films with high film quality and high step coverage.

ALD systems are compact atomic layer deposition systems for research and development (ALD = Atomic Layer Deposition) that enable precise and uniform control of each atomic layer and the deposition of films with high film quality and step coverage even on uneven surfaces.

Uses

Oxide films (AL2O3, HfO2, SiO2, TiO2) can be deposited by surface chemical reactions with water or ozone using raw materials in precursor bottles, as deposition material.

Products

SAL1000 Desktop-type ALD

This entry-level model of ALD equipment can easily produce thin films one atomic layer at a time.

Simple, easy operation and a portable design make it easy to move around the table-top model.

SAL1000B Powder ALD

SAL1000B is an ALD system that enables all-round deposition on powder.

The main feature of the machine is that it can deposit films on powder by tilting + rotating + vibrating.

The ability to deposit an all-round film on powder enables it to play an active role in the development of new materials, for example.

SAL1000G ALD with Glove Box

A desk top ALD system that combines functionality and performance, capable of depositing films on wafers or powders.

Equipped with a glove box, this model meets the deposition needs of anaerobic materials that react with oxidation and the atmosphere.

SAL3000 Compact ALD system with full functions.

The SAL3000 model is 40% smaller in width than the previous standard model.

In addition to the conventional depot-down type specification, a ‘depot-up’ type is available to further reduce particle adhesion to the substrate.

Expandable ALD

A product that has succeeded in significantly downsizing the main unit while maintaining the deposition performance of the SAL3000.

Furthermore, it is a high-performance ALD system that can be combined with other equipment to support a wide range of deposition processes.

More information on SAL3000Plus

Evaporation equipment for depositing films on substrates by evaporating metallic materials installed in a heat source.

Deposition equipment heats deposition materials such as metals and metal oxides in a vacuum and forms thin films by attaching and depositing evaporated atoms on the surface of a substrate or board.

Uses

Suitable for research and development where film thickness can be controlled with a quartz crystal film thickness gauge and is intended for the deposition of metal or oxide films on substrates.

Products

SEV2000Plus Compact evaporation systems for R&D

The SEV2000Plus allows automatic exhaust operation from a touch screen and has various interlocks to prevent malfunctions.

It features a small, footprint-saving design and the possibility of expansion with Plus series equipment.

More information on SEV2000Plus

Annealing equipment for high temperature heat treatment to substrates.

Annealing equipment is equipment capable of performing high-temperature heat treatment and gas replacement on substrates.

Pressure can also be controlled during heat treatment by introducing inert gas.

Uses

The film can be modified by heating the wafer at high temperatures in a vacuum.

Products

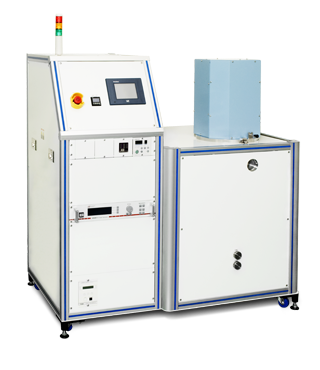

SAN1000 Desktop Annealing・Nitriding Treatment Equipment

The SAN1000 can make a heat treatment for substrates up to 4 inches by infrared irradiation in a clean environment in a vacuum or gas atmosphere.

Furthermore, a cooling mechanism allows substrates to be removed from the machine after processing in a short time.

SAN2000Plus Annealing system capable of plasma treatment.

As with SAN1000, heat treatment can be carried out in a clean environment.

In addition, it combines plasma process technology capable of removing organic and metallic films from the substrate surface and surface modification, and is rich in functionality, performing both pre- and post-process processing for substrate deposition.

More information on SAN2000Plus

Transfer unit to transport wafers to the equipment under vacuum.

This is the substrate transfer unit for complex equipment that can be freely combined with up to three major types of equipment, such as ALD equipment, sputtering equipment and annealing equipment.

Uses

It plays the role of a core device responsible for the transfer of substrates in the equipment verb and can also be used as a load lock chamber.

The combined system also allows substrates to be passed to the process chambers of the respective equipment without exposing them to the atmosphere.

Products

STR2000 Transfer Unit

The structure incorporates a frog-leg transfer (substrate transfer mechanism) and rectangular gate valve in the core chamber, providing high quality, performance, reliability, safety and low cost.

Heating furnaces with higher precision temperature control.

Heating furnaces heat objects to a predetermined temperature and are used for multiple purposes, such as rolling, forging and melting.

It is mainly used to increase the extensibility, ductility, etc. of metals. In addition to pressure control, gas and

Uses

Atmosphere furnaces equipped with an annular furnace to heat quartz or ceramic core tubes.

Atmosphere control systems can be selected and constructed to suit R&D use.

Products

SAF3000 Atmosphere Controlled Furnace

The SAF3000 is a tubular heating furnace with thermocouples mounted inside the core tube.

An automatic furnace body sliding mechanism enables rapid heating and cooling by moving the furnace body.

In addition to batch steam introduction and continuous steam introduction using a distillation machine, steam traps can be used to adjust the steam volume.

Space chambers for space environment testing, etc

Space chambers can be used to evaluate the space environmental resistance of components and materials for satellites and space shuttles.

Miniaturization will make them widely used in aerospace industry related fields.

Uses

A wide variety of experiments can be carried out, including PFM (proto-flight model) tests of hyperspectral sensors, performance evaluation of various observation instruments and environmental tests of launch vehicle onboard components.

Products

Space Chamber -Φ1m-

Easy to handle as an evaluation of small components and a full-scale device equipped with a cooling shroud.

The abundance of introduction ports makes it versatile.

More information on Space Chamber

In summary: Leave it to us! if you are in need of vacuum equipment,

In this article, we have introduced the types of vacuum equipment and products available at SUGA in Hokkaido, Japan.

We supply annealing equipment for film quality improvement applications after film deposition as vacuum equipment, and provide vacuum piping components required for the configuration of vacuum equipment and vacuum facilities.

We also offer support for servicing, repairs and modifications, please contact us for more information.