We, SUGA manufacture thin-film devices based on the vacuum principle.

In order to familiarize you with the principles of vacuum, we will talk about a bag of snacks as an example to explain ‘vacuum evaporation’.

Vacuum evaporation and snacks.

Have you ever looked at the inside of a bag of snacks?

Most of the time, the inside of the bag has a silver membrane.

This silvery film is a metal film and is made from ‘aluminum’.

The ‘vacuum evaporation method’ is applied to produce this film.

Snack food bags are made of plastic film, which usually allows water vapor, oxygen, nitrogen, and carbon dioxide to pass through.

However, if the bag contains potato chips fried in oil, the oil must be prevented from oxidation in order to preserve quality.

This is effectively prevented by the aluminum deposited bags.

How the aluminum is deposited on the underside of the bag is shown next.

‘Vacuum evaporation’ for depositing aluminum on snack bags.

Vacuum evaporation method is used to apply aluminum to the underside of snack bags.

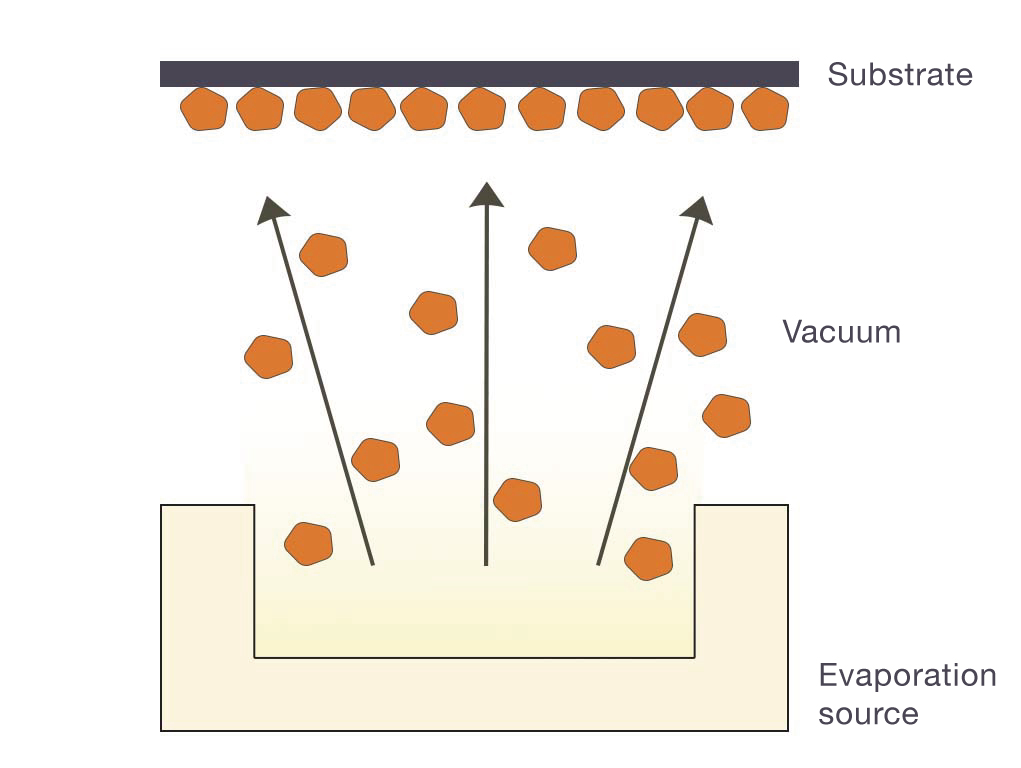

First, the principles of the vacuum evaporation method are briefly explained.

- The vacuum vessel is equipped with an evaporation source.

- When an evaporating material is heated, it begins to evaporate. (Imagine steam coming out of a pan)

- The evaporated material adheres to the substrate placed in the container and forms a film.

The deposition of films using evaporation and vacuum is known as the ‘vacuum evaporation method’.

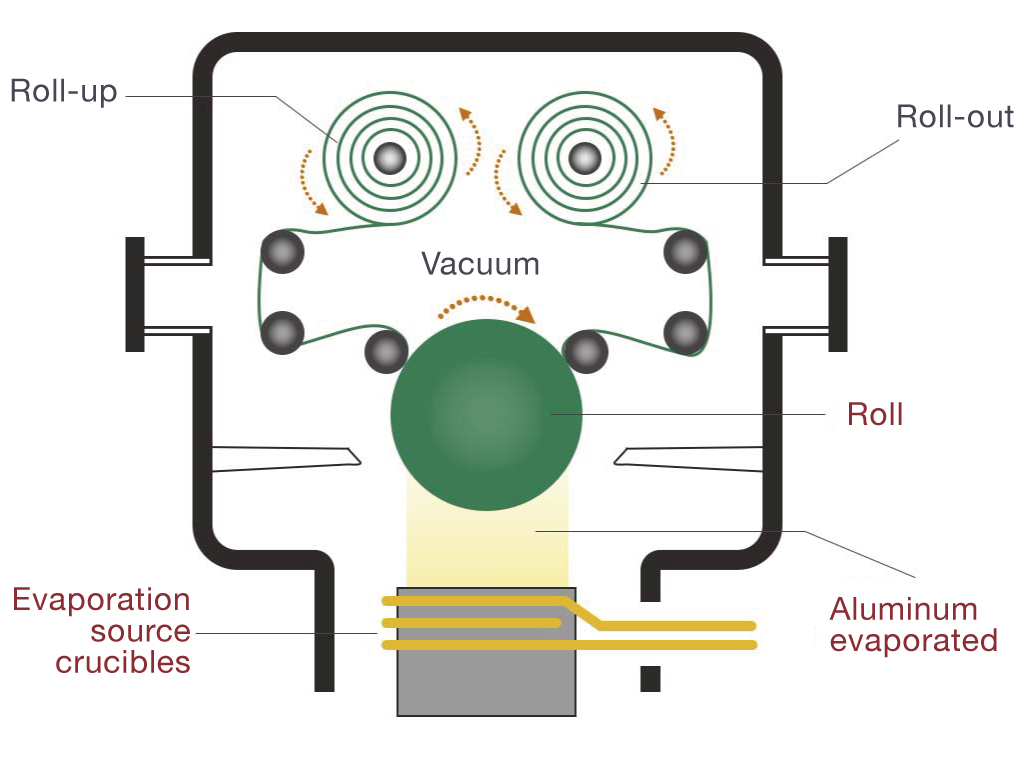

There are different types of vacuum evaporation methods, and ‘roll-up vacuum evaporation’ is used to deposit the film on the underside of snack bags.

Prepare several meters of ‘roll-out film’ and rolls to roll it up.

Several evaporation source crucibles are placed under it and filled with the evaporation material, aluminum.

The crucible is made of carbon, with a high-frequency coil wrapped around the outside.

The carbon crucible is heated using an IH-like principle.

The aluminum in the crucible then melts and evaporates, forming an aluminum film on the roll-out film.

When all films have been deposited, the process is complete.

The aluminum film will be around 50 nanometers (0.00005 mm) thick and is then printed on top of the deposited film and processed into snack bags.

Summary

In this article, vacuum evaporation was explained using snack bags as an example.

We manufacture and sell vacuum-based deposition equipment.

See the products here.