TiN is commonly deposited for semiconductors as the barrier layer in between Oxide film layer (SiO2, etc.) and Cupper to prevent the integration.

For another application, TiN is often applied as hard coating aimed at extending the life of cutting tools.

It’s known that TiN film has high hardness and excellent heat resistance which are sufficient to prevent baking and melting damage.

The performance of TiN film is highly appreciated not only for the cutting tools but also for the wear resistant engine parts and golf heads.

Needless to say, tack force is very important for those applications in addition to the hardness and ware resistance and film deposition seems to be the only solution for such extreme demands.

Sputtering with Ti target using only argon gas would create the silver-colored metallic titanium film, but when nitrogen gas is added to argon gas, golden shine colored very hard TiN film is formed.

This is the phenomenon which is caused by one of the reactive sputtering when the sputtered titanium is nitrided.

The residual stress inside the film changes as the nitrogen gas partial pressure ratio with respect to argon gas increases or decreases. The residual stress also increases and the hardness of the film tends to increase when the nitrogen partial pressure ratio is large,

However, on the contrary, the film would peel off with a slight impact if the residual stress is large. So, it is important to cut and try in order to find the optimum condition for the film deposition that suit the purpose.

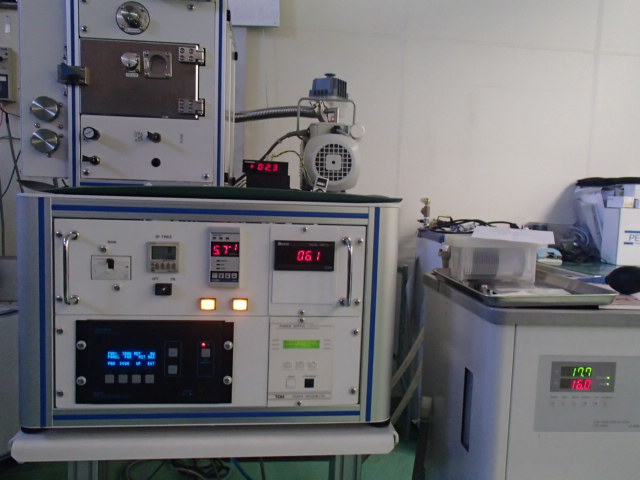

Now, let us introduce an example of film deposition of TiN using the reactive sputtering method with our desktop sputtering system, SSP1000.

Desk top type sputtering system, SSP1000

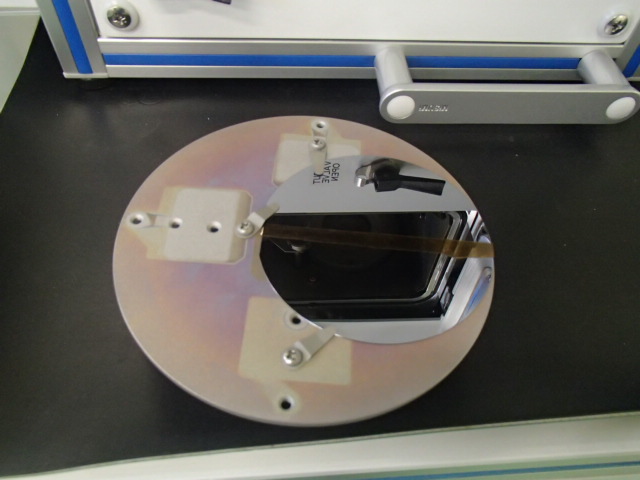

Silicon wafer before the film deposition (Silver)

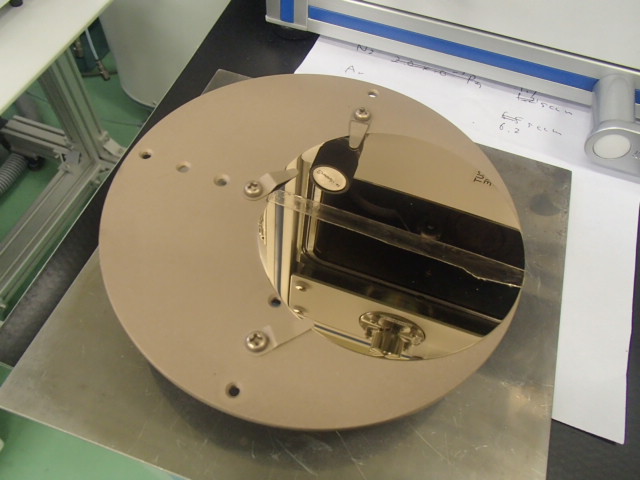

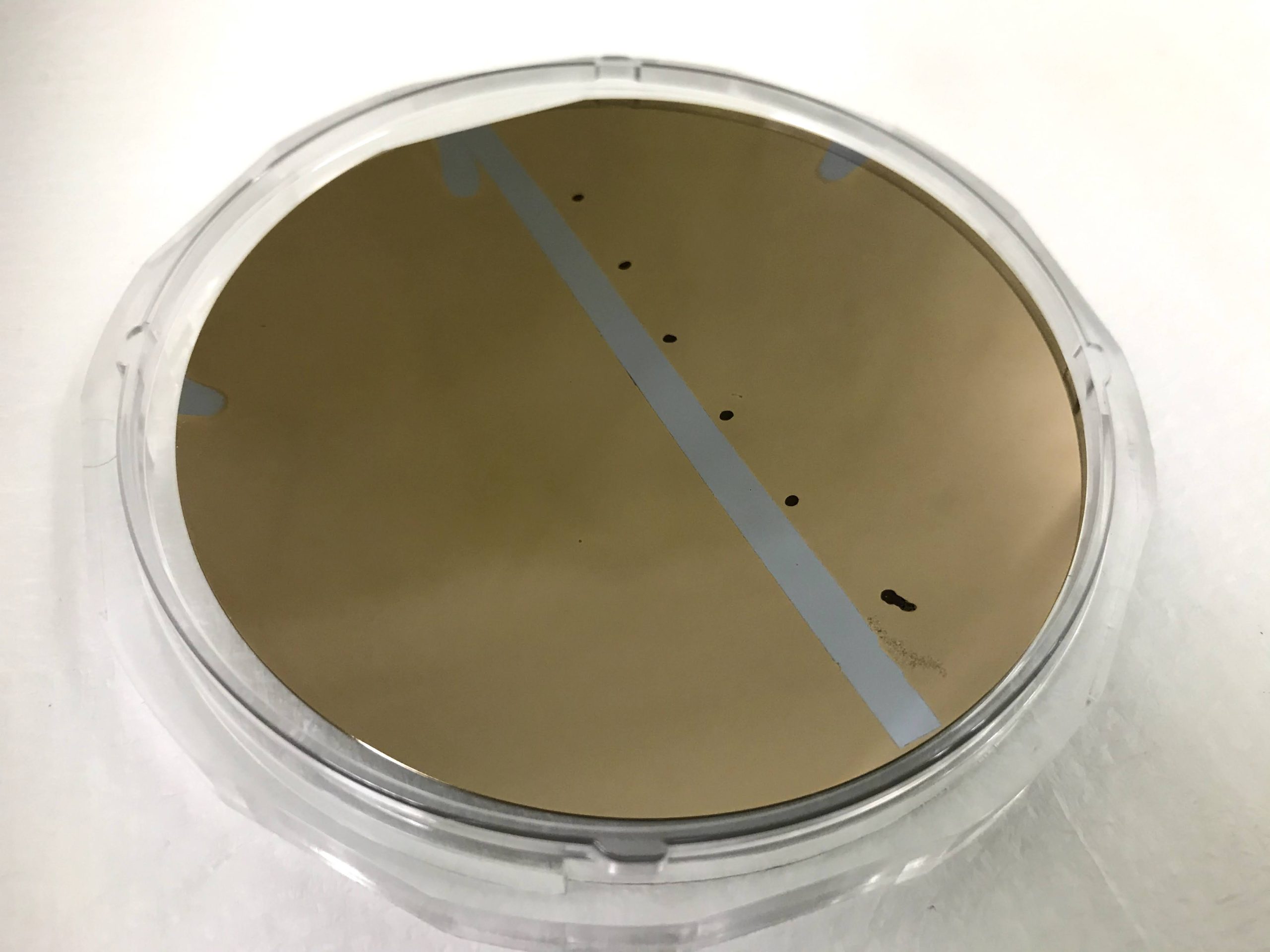

Silicon wafer after TiN film deposition (turn into Gold)

The masking tape has been peeled off.

It’s easy to observe the color change.

The black dots observed on the surface are marking points for measurement of film thickness using a profilometer.

SSP1000, desktop sputtering system

Note: This report shows an example of film deposition using SSP1000. Quality such as color and hardness are not guaranteed.