We introduce a desk model recommended point to be able to make the placement change into.

Desk-top type model can allow you to make a flexible layout change.

It is great in being small.

Don’t underestimate this small equipment.

Small sputtering equipment

Desk-top type

Deposition direction can be changed

We share with you the recommended point and characteristic features of small sputtering equipment.

We show you the operation process for your image to set this equipment on a desk in a laboratory.

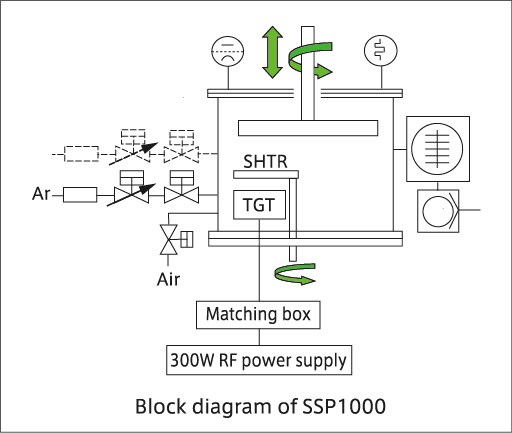

SSP1000 cubic sputtering equipment is the desk top one realizing the high performance, the high quality and the affordable price.

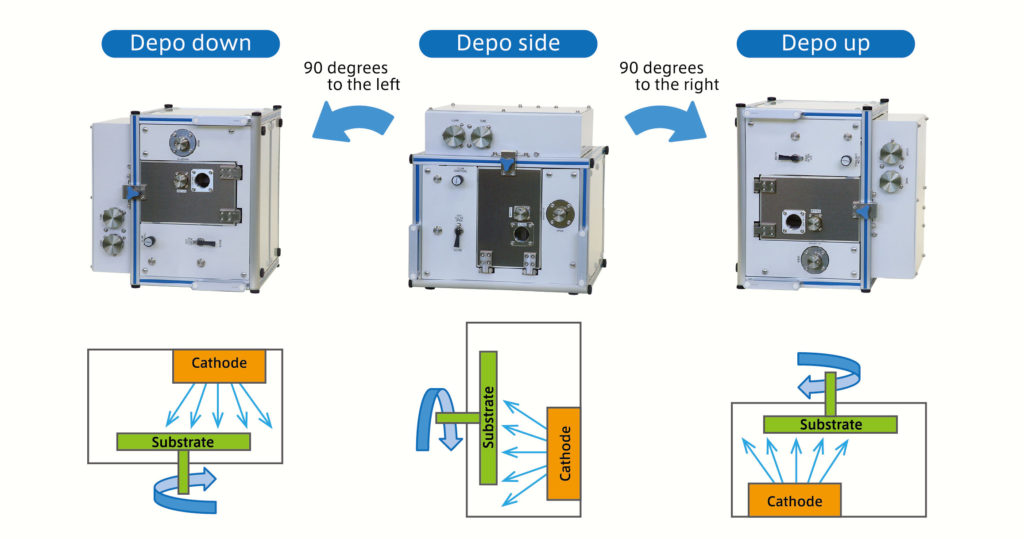

The structure of the flexible deposition direction makes it possible to conduct experiment for three different deposition directions.

Furthermore, this RF power supply installed equipment can take care of depositions not only for the metal but also insulation target.

It is small but cost saving “the device which is kind to environment and cost” to be able to use for various kinds of experiments cheaply although being small.

It’s small but “Environmental and budget-friendly equipment” for various kinds of experiments.

contents

Dimensions, outline, use

Recommended point of SSP 1000

Operation scenery

Characteristic of SSP 1000

Introduction video of SSP 1000

Contents

Small sputtering equipment SSP 1000

Dimensions of the main body

W608mm×D608mm×H766mm

Outline, use

Desk-top type model RF sputtering equipment for research and development

Thin-film deposition, which is essential for the manufacture of semiconductors, electronic devices and functional materials, is possible.

It can be available in research and development such as a metal film, the insulation film, a transmission film, the insulation film, a protective film, a reflection film, a catalyst, coating, a circuit, a battery, MEMS, the new materials development.

The chamber weights only 31kg by machining the aluminum block.

The sputter UP, SIDE and DOWN is selectable, depending on how you place the chamber.

Recommended point of SSP1000

This compact model won’t take a back seat to any larger models in a deposition performance realizing film thickness distribution of ±5% or less of withinΦ100mm.

The selection of three deposition directions can obtain the best performance.

User can setup the device.

You can play with many options as you desire.

We assure you the best after-sales service.

Operation scenery

The operation in the limited space makes it possible to set the small sputtering equipment on the desk.

Characteristic of SSP 1000

[characteristic 1]

It adopts the same cathode as the upper model

[characteristic 2]

The film formation direction can be changed freely

[characteristic 3]

RF power supply

[characteristic 4]

Automatic vacuum exhaust system

[characteristic 5]

Operation system by the manual operation

[characteristic 6]

Interlock function

[characteristic 7]

Position to put desk-top

[characteristic 8]

Installation and the setup of the device are possible by user

[characteristic 1] It adopts the same cathode as the upper model

It carries φ 2 inches magnetron cathodal one engine (with a shutter) and achieves less than film thickness distribution ±5% within φ 100mm.

We did not compromise but adopted cathode structure same as the upper model even for this entry model.

When you want to deposit magnetic materials, you can cope with the film deposition of magnetic material by replacing a water-cooled magnet with the strong magnet field magnet (extra-cost).

[characteristic 2] The film formation direction can be changed freely

As the name of cubic sputter indicates, it is possible to change the deposition direction in three directions: sputtering UP, sputtering SIDE, and sputtering DOWN by pulling round the dice-shaped chamber (deposition chamber).

・Sputtering UP

Most of the users employ this film deposition method since this is the best way to prevent the adhesion of the particle to the substrate.

It is excellent in workability during maintenance since the target faces downward.

・Sputtering SIDE

This arrangement prevents particles from adhering to the substrate and flakes from adhering to the target and ensures high quality deposition.

The workability when fine-tuning the distance between target and substrate (T/S) is superior among the three ways.

・Sputtering DOWN

It is used when arranging irregular substrates and small parts for deposition because the sample is simply placed on the substrate holder.

Constant attention is required because particles tend to fall on the substrate side.

When the placement of the chamber is changed, the gas and cooling water lines need to be disconnected. It is recommended that these utilities are connected with flexible hoses and flexible tubes, etc., rather than fixed rigid piping.

[characteristic 3] RF power supply(with pulse oscillation function)

The high-frequency RF power supply with pulse oscillation function enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

[characteristic 4] Automatic vacuum exhaust system

The operation of Start and Stop for vacuum can be easily done with one button only.

For exhaust, the rotary pump starts up and the turbo molecular pump starts up until it rotates at a steady state. When it stops, the rotary pump stops after the turbo molecular pump stops, and then all the operations up to atmospheric venting are automatically performed.

It is also possible to recognize whether it is exhausting or stopped by the illumination of the button’s lamp

Therefore, the equipment is designed for safe use without the risk of accidentally damaging the equipment during operations involving the exhaust system.

[characteristic 5] Operation system by the manual operation

Various gauges and operating components are efficiently arranged for the functions required during the deposition process, such as RF power control, pressure display, flow rate display, sputter timer, matching volume, substrate rotation button, gas introduction and flow rate control, shutter and buzzer functions.

If the optional chamber bake function is installed, a heater on/off switch is also added.

[characteristic 6] Interlock function

The exhaust system and RF power supply are safe to use as they are interlocked to prevent them from running out of control or being damaged by accidental operation.

In particular, the RF power supply is interlocked so that the plasma discharge is not powered unless a number of conditions are met, such as the operation signal of the exhaust system pump, the pressure information from the vacuum gauge and the cooling water sensor signal.

[characteristic 7] Position to put desk-top

Both stacked (stacked) and parallel (horizontal) arrangements are possible to accommodate a variety of installation environments.

Moreover, the power supply unit and pump can be floor-mounted and only the chamber can be placed on a rack.

If the power supply and chamber are to be separately installed, you are kindly requested to advise us beforehand as cable lengths etc. may be insufficient.

In addition, a dedicated stand (for stack placement) is available as an option.

[characteristic 8] Installation and the setup of the device are possible by user

The SSP1000 is basically set-up and operation training by our service personnel at the time of delivery, but it is not difficult for users who regularly handle vacuum equipment (especially sputtering equipment) to set it up on their own.

The SSP1000 is basically set up and operated by our service personnel at the time of delivery, but it is not difficult to set it up by yourself if you are familiar with the vacuum equipment particularly sputtering equipment.

To avoid incorrect plugging, the wiring can be identified by different connector shapes, labels, etc.

For cooling water, process gases and electricity, the difficulty level is not high for those who have experience in connecting utility power.

However, if you still have concerns about the operation and daily maintenance of the unit after reading the manual, be sure to undergo operation training by us to prevent accidents.

Introduction video of SSP 1000

If you are interested in our desk top type sputtering equipment, please feel free to contact AGUS.