SUGA, located in Hokuto City near Hakodate city, Hokkaido, was founded in 1946 as a repair company for fishery equipment. Addition to the repair work, we have been manufacturing vacuum equipment and devices with the aim of further developing and improving its products.

In this issue, we would like to introduce ALD system of SUGA.

Our ALD system is a compact atomic layer deposition system for research and development that provides uniform control of each atomic layer and enables deposition of high quality films with high step coverage.

Please refer to the following section for a summary of features and applications.

Contents

- 1 1 SAL1000 (desktop ALD system) can easily produce thin films one atomic layer each.

- 2 2 SAL1000B (ALD system for powder deposition) for all-round deposition on powder.

- 3 3 SAL1000G (ALD system with glove box)

- 4 4 Compact, full-featured SAL3000 (ALD system)

- 5 5 SAL3000Plus (extendable ALD system) for a wide range of experiments with its compact size and combination with other equipment.

- 6 Summary.

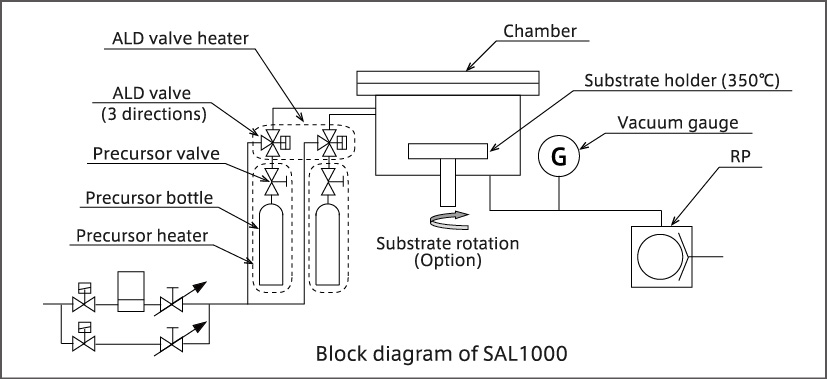

1 SAL1000 (desktop ALD system) can easily produce thin films one atomic layer each.

The ALD (ALD = Atomic Layer Deposition) system can realize precise deposition control for each atomic layer and the formation of thin films that are uniform and have excellent step coverage even on uneven surfaces.

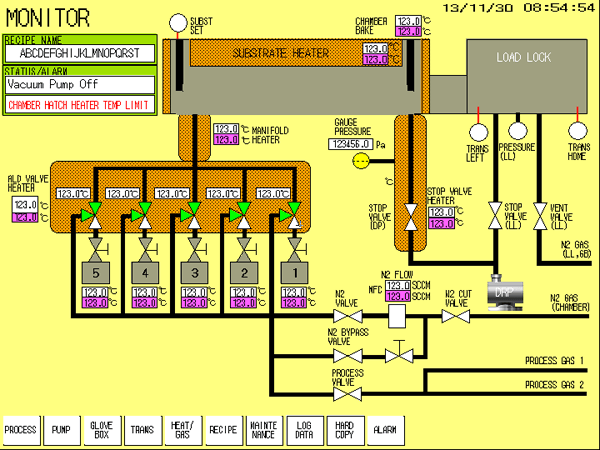

Characteristics.

- It allows uniform, pinhole-free deposition on the substrate surface with one atomic layer each.

- Simple and straightforward hardware operation. Buttons for disposal operations and a valve for adjusting the gas outflow are also located on the front panel.

- The touch panel software has designed a screen layout that facilitates recognition of the conditions during deposition.

Application.

ALD (Atomic Layer Deposition) system for research and development.

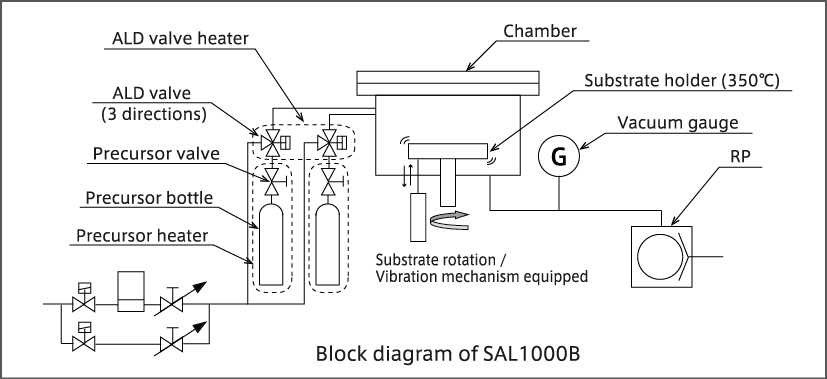

2 SAL1000B (ALD system for powder deposition) for all-round deposition on powder.

Oxide films (AL2O3, HfO2, SiO2, TiO2) can be obtained by surface chemical reaction with water or ozone using raw materials in precursor bottles, called precursors, as deposition materials.

Characteristics.

- Due to its excellent step coverage, it is suitable for deposition on uneven surface profiles and three-dimensional shapes.

- The touch panel software has designed a screen layout that facilitates recognition of the conditions during deposition.

- For efficient powder deposition, the tilting frame can be adjusted so that it is tilted forward by up to 45°.

Application.

Table-top type system for research and development. The ability to deposit an all-round film on powder allows it to be used in fields involving powder and granular materials, for example, in the development of new materials.

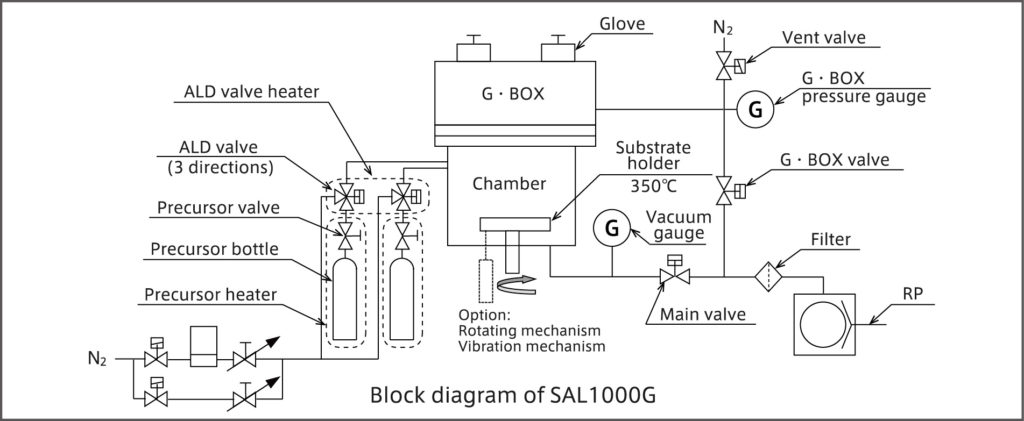

3 SAL1000G (ALD system with glove box)

This model is a table-top type ALD system equipped with a glove box to meet deposition needs with anaerobic materials that react with oxidation and the atmosphere.

Characteristics.

- Table-top type ALD system with acrylic glovebox for vacuum evacuation and nitrogen venting.

- Deposition is possible on wafer geometries up to 4 inch. It is also equipped with a MAX 350°C heating mechanism. In tests with AL2O3, it has a film thickness distribution performance of less than 3% within Φ100 mm.

- A large handle is attached at the main unit as a portable tabletop system.

Application.

Table-top ALD (atomic layer deposition) system for research and development.

4 Compact, full-featured SAL3000 (ALD system)

In addition to the conventional depot-down type specification, a ‘depot-up’ type is available to further reduce particle adhesion to the substrate.

Characteristics.

- For substrate sizes up to φ100 mm, the performance of ±3% film thickness distribution, uniform, pinhole-free layered deposition is possible.

- You can choose between depot-down (substrate face-up) SAL3000D and depot-up (substrate face-down) SAL3000U specifications.

- The touch panel is positioned at an elevated angle and it has excellent visibility and operability.

Application.

ALD (Atomic Layer Deposition) system for research and development.

5 SAL3000Plus (extendable ALD system) for a wide range of experiments with its compact size and combination with other equipment.

The ALD (ALD = Atomic Layer Deposition) system realizes precise deposition control for each atomic layer and the formation of thin films that are uniform and have excellent step coverage even on uneven surfaces.

Characteristics.

- High-quality deposition distribution with excellent step coverage, making it suitable for deposition on uneven surface geometries and three-dimensional shapes.

- You can choose between the SAL3000+D depot-down (substrate face-up) or SAL3000+U depot-up (substrate face-down) versions of the SAL3000Plus.

- A port for expansion is provided on the side of the unit, which can be connected to the transfer unit STR2000 to obtain a load lock function.

Application.

Oxide films (AL2O3, HfO2, SiO2, TiO2) can be obtained by surface chemical reaction with water or ozone using raw materials in precursor bottles, called precursors, as deposition materials.

Summary.

SUGA manufactures vacuum equipment, including the ALD equipment described here, as well as annealing equipment for improving film quality after deposition.

We also offer support for servicing, repairs and modifications, please contact us for more information.