Annealing equipment is capable of high-temperature heat treatment, gas replacement and plasma treatment processing on substrates.

It plays a very important role in film quality improvement applications after deposition by sputtering equipment.

This article explains two types of annealing equipment of Suga.

Founded in 1946 as a repairer of equipment for fishing boats, we manufacture and sell vacuum equipment and vacuum devices, and is now expanding its activities mainly to serve universities and research institutions.

Please refer to the principles, characteristics and performance of annealing equipment.

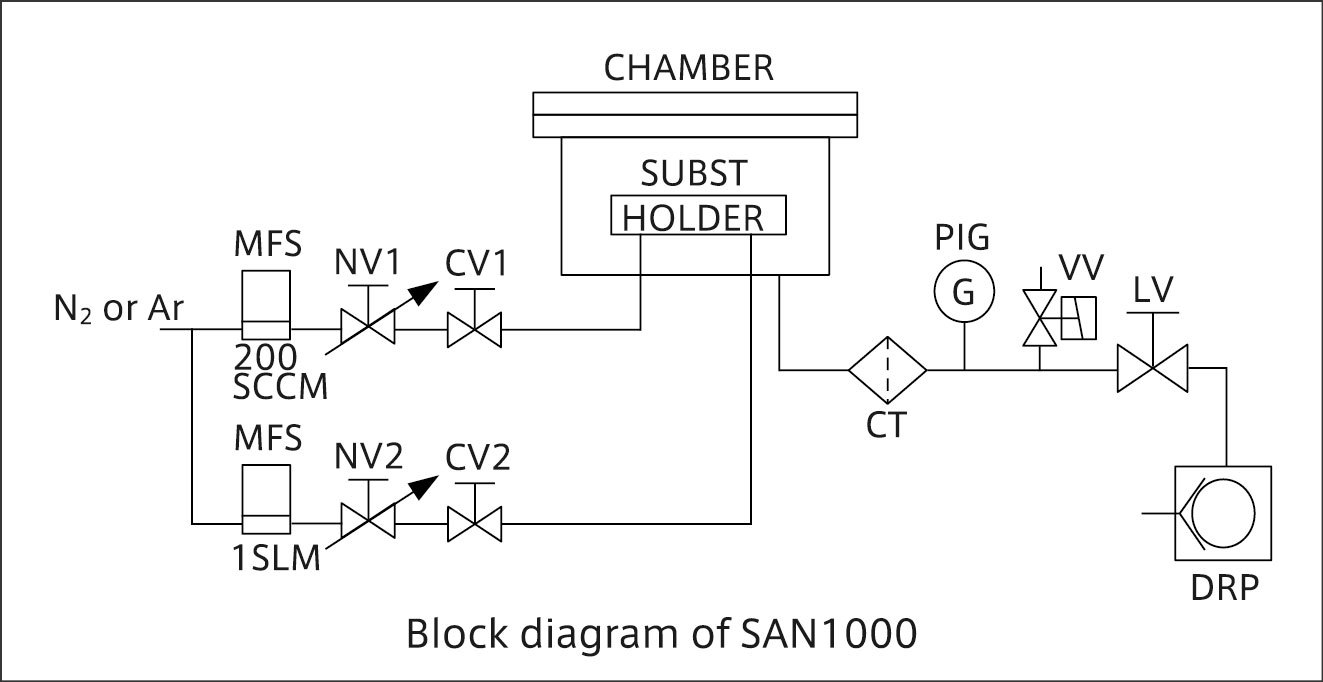

Principle of the SAN1000 table-top annealing and nitriding treatment system.

The SAN1000 can control the pressure during high-temperature heat treatment (annealing) and heat treatment by introducing inert gas to the substrate.

Principles and applications

Substrates up to 4 inch can be heat-treated in a clean environment with vacuum or inert gas atmosphere by means of infrared radiation.

It is equipped with a cooling mechanism and it employs batch system that allows substrates to be taken out after processing in a short time.

Characteristics.

At heat treatment, a needle valve regulate the flow rate.

It allows heat treatment in various vacuum atmospheres.

It also has the versatility to rapidly raise temperatures from 200°C to a maximum of 1000°C.

Rapid cooling is also possible due to the combination of a water-cooled cold-wall structure and a substrate-cooling gas mechanism.

Performance

The optimized PID algorithm provides excellent temperature control.

A cooling mechanism allows quick removal after treatment, and repeated treatment can be carried out in a short time.

The chamber is entirely water-cooled, with various interlocks for vacuum evacuation, heating, cooling water flow rate, etc., to ensure a high level of safety.

Standard specification

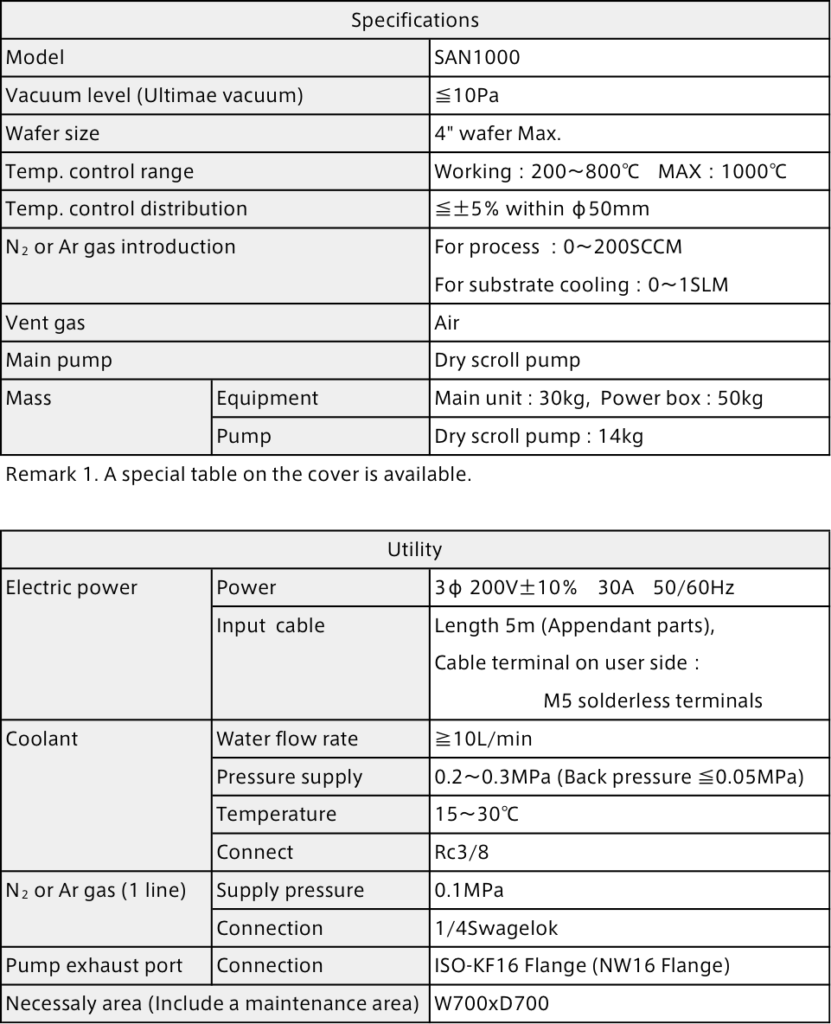

Specification

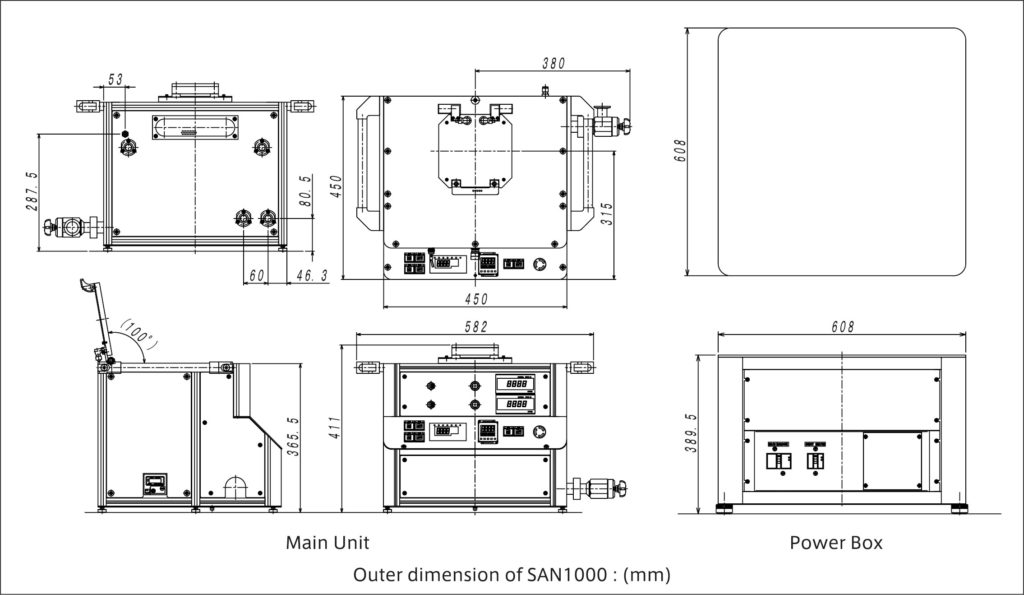

Outer dimension

Learn more about the SAN1000 table-top annealing and nitriding treatment system.

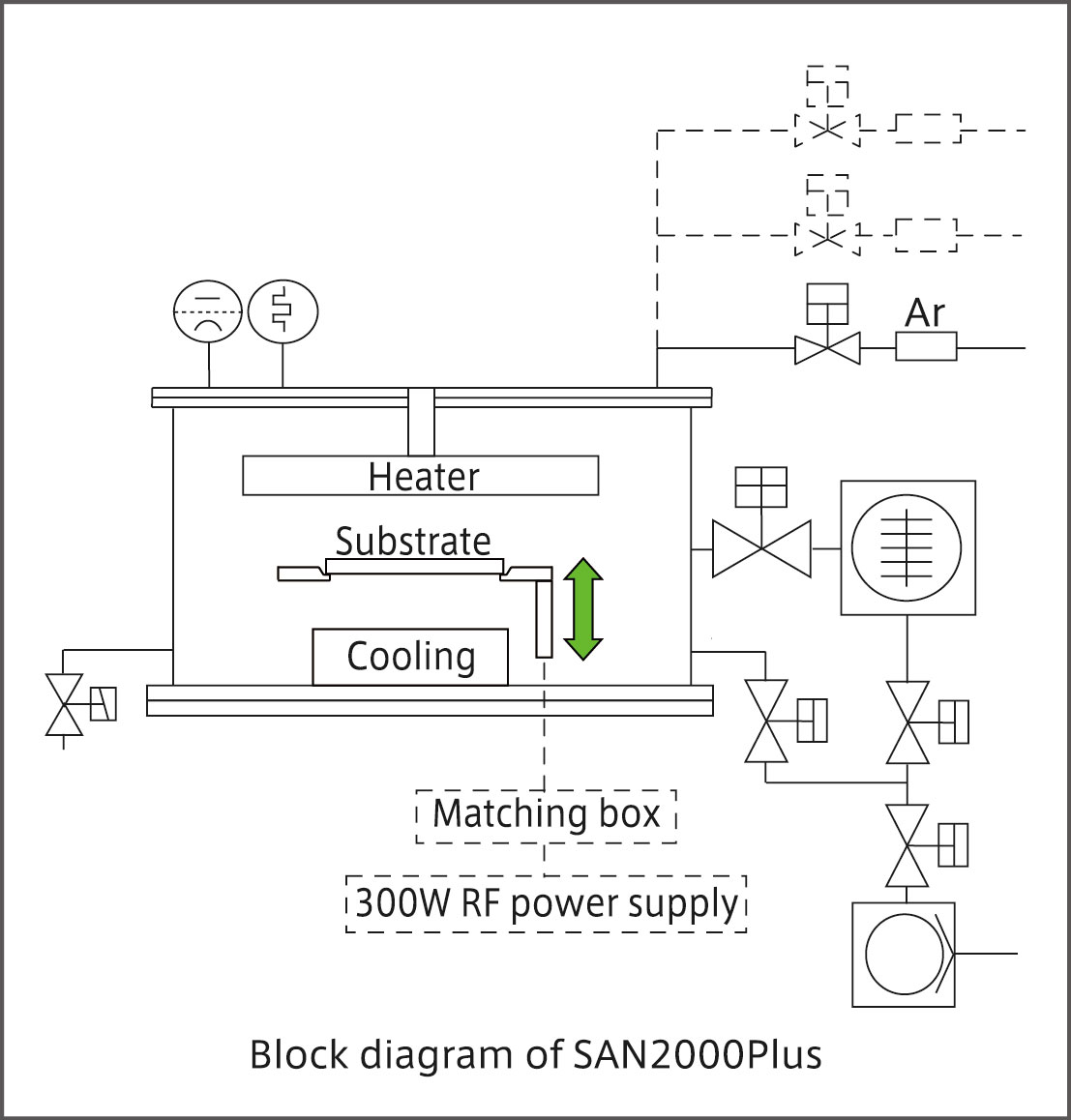

Principle of the SAN2000Plus annealing system.

It is possible to perform high-temperature heat treatment (annealing) on substrates and heat treatment by introducing reactive gases.

Principles and applications

Substrates up to 4 inch can be heat-treated in a vacuum or in a clean environment with vacuum or inert gas atmosphere by means of powerful infrared radiation.

Furthermore, by adding plasma process technology that can remove organic and metal films from the substrate surface and modify the surface, this single unit can be used for both pre- and post-processing of substrate deposition.

Characteristics

The SAN2000Plus enables substrate heat treatment in a high vacuum condition obtained by turbo molecular pump.

Uniform heat treatment is possible, as well as substrate surface cleaning and surface modification as a plasma surface treatment system.

High-speed cooling is also applicable due to the combination of a water-cooled cold-wall structure and a substrate-cooling gas mechanism.

Performance

It has excellent temperature control, operability and safety features which can be achieved by the optimized PID algorithm and various interlocks.

Up to 19 steps and 30 different program patterns can be set.

Other outstanding performance features include the ability to remove natural oxide film, dirt and other contaminants prior to substrate deposition, to improve film adhesion, and to perform surface activation treatments such as hydrophilic treatment.

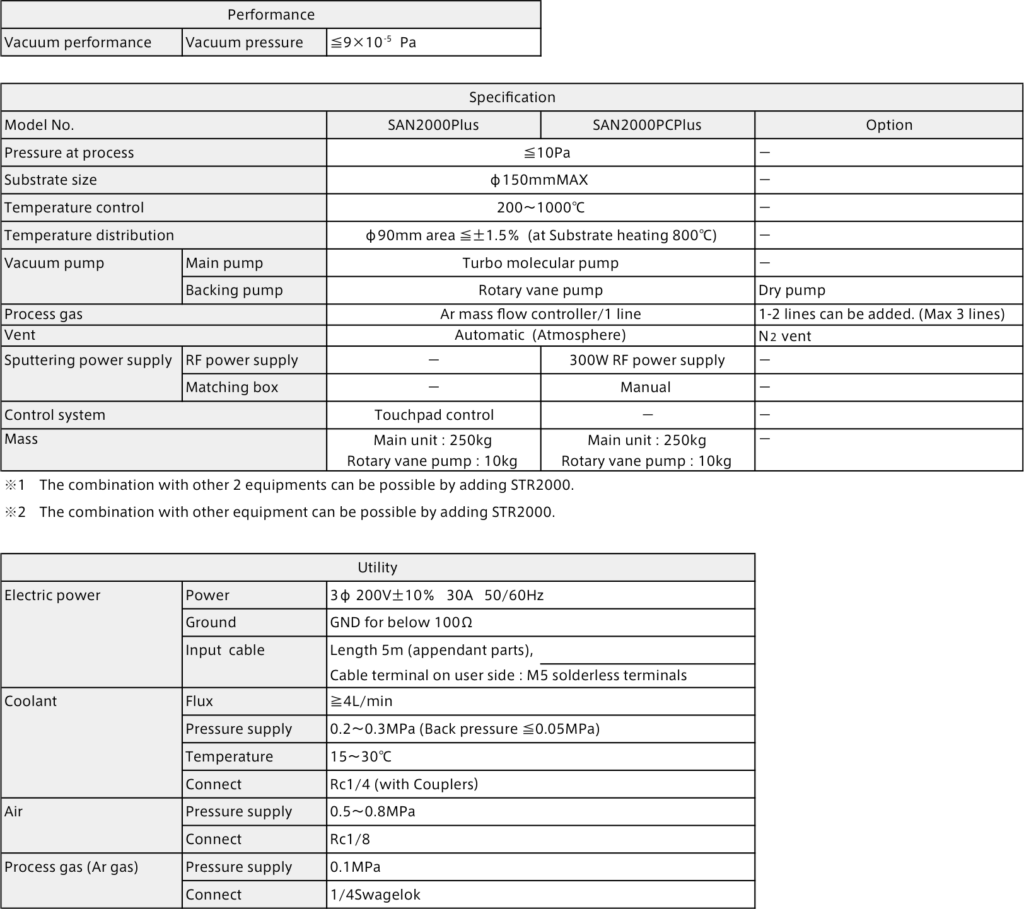

Standard specification

Specification

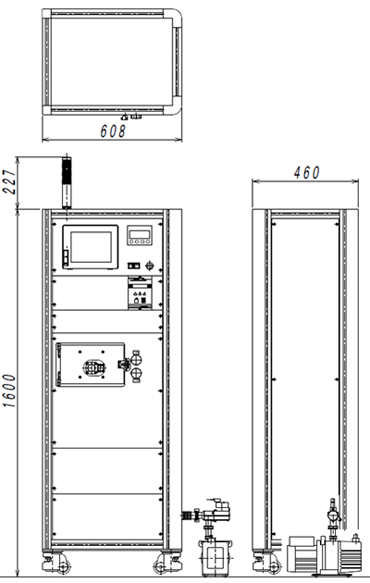

Outer dimension

Find out more about the SAN2000Plus annealing system.

Summary

In this article, the principle, features and performance of our annealing equipment have been explained.

Annealing system is used to improve film quality, but sputtering equipment is used at a preliminary step.

Suga’s sputtering equipment is also available at your service.

製品一覧を見てみる

スパッタ装置についてはこちら

Click here for information on sputtering equipment.