![[List] There are five types of vacuum equipment! Show 9 popular recommendations.](https://agus.co.jp/wp-content/uploads/2021/09/image15.png)

Vacuum equipment is often used for R&D purposes, and its use may vary depends on the type of equipment.

In this issue, we introduce five types of vacuum equipment and nine carefully selected vacuum devices.

Founded in 1946, SUGA has expanded its activities to sell its own sputtering equipment to universities and research institutes.

Here is the introduction of SUGA’s vacuum equipment, so please take a look at it.

Contents

- 1 Japan’s only photoemission electron microscopy /PEEM

- 2 Sputtering equipment for deposition systems using the sputtering phenomenon

- 3 ALD system which is capable of depositing films with high film quality and high step coverage.

- 4 Evaporation equipment for depositing films on substrates by evaporating metallic materials installed in a heat source.

- 5 Annealing systems that enable film modification by heating wafers to high temperatures in a vacuum.

- 6 Summary

Japan’s only photoemission electron microscopy /PEEM

MyPEEM (Photoemission electron microscopy)

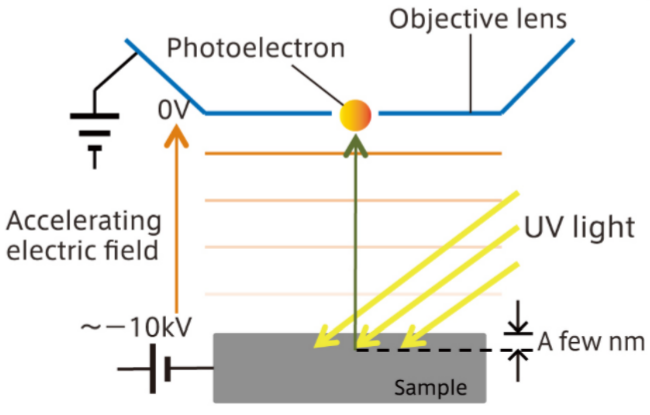

Photoelectrons (secondary electrons) excited by irradiating the sample with UV light are accelerated by a negative high voltage applied to the sample.

The chamber, which is the photoelectron pathway, can be placed at ground potential making it safe and compact.

Characteristic

- Stand-alone type can be used without additional options.

- making it easy to replace the various light sources.

- Three contrast apertures can be selected manually.

Uses

The main uses are to track the dynamic processes of thin-film growth and catalytic reactions.

It can be applied to gas adsorption and spin observation using circularly polarized UV light.

Sputtering equipment for deposition systems using the sputtering phenomenon

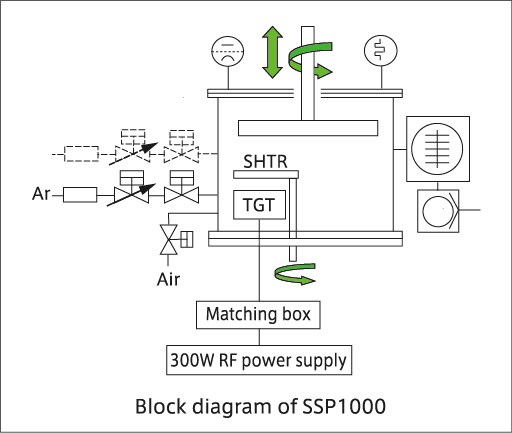

SSP1000 (Cubic Sputtering Equipment)

This is the desk-top type and its chamber weights only 31kg by machining the aluminum block.

Characteristic

- The dice-shaped chamber (deposition chamber) can change the deposition direction.

- RF power supply enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

Uses

It is used in research and development applications such as metal films, insulating films, conductive films, protective films, reflective films, catalysts, coatings, circuits, batteries, MEMS and advanced materials.

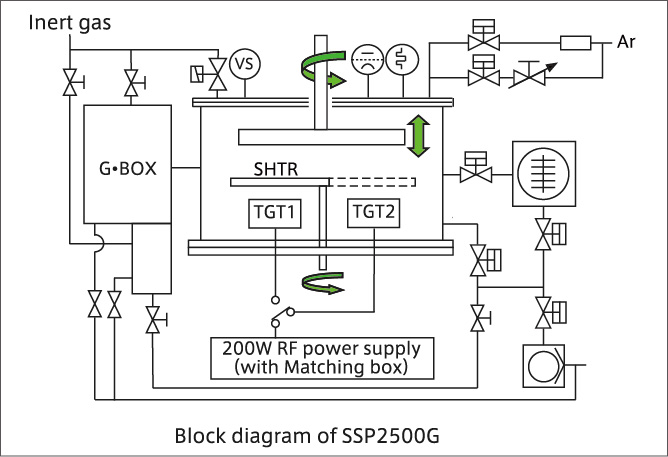

SSP2500G (Sputtering Equipment with Glove Box)

It is equipped with a simplified glove box for both vacuum and gas displacement.

Therefore, deposition with substrate samples can be used with confidence.

Characteristic

- It adopts the same cathode as the upper model

- The dice-shaped chamber (deposition chamber) can change the deposition direction.

- RF power supply enables stable deposition even on targets made of insulating materials, which are prone to abnormal discharges.

Uses

It is used in research and development applications such as metal films, insulating films, conductive films, protective films, reflective films, catalysts, coatings, circuits, batteries, MEMS and advanced materials.

For more information about other sputtering system.

ALD system which is capable of depositing films with high film quality and high step coverage.

SAL1000 (Desktop-type ALD Equipment)

ALD( atomic layer deposition)system realizes precise deposition control for each atomic layer and enables the formation of thin films that are uniform and have excellent step coverage even on uneven surfaces.

Characteristic

- It allows uniform, pinhole-free deposition on the substrate surface with one atomic layer each.

- Simple and easy hardware operation.

- Buttons for disposal operations and a valve for adjusting the gas outflow are also located on the front panel.

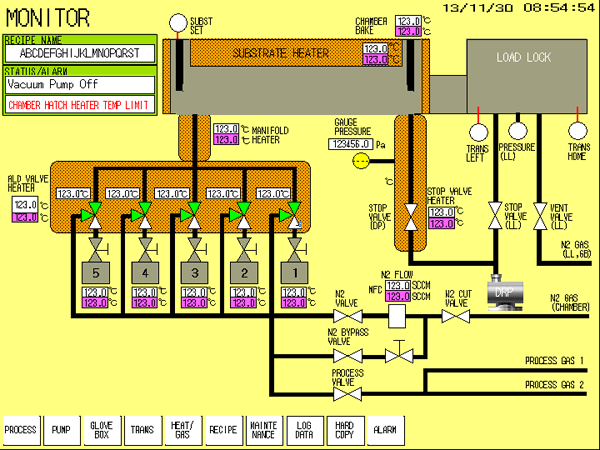

- The touch panel software has designed a screen layout that facilitates recognition of the conditions during deposition.

Uses

ALD (Atomic Layer Deposition) system for research and development.

SAL1000G (ALD with Glove Box)

This model is a table-top ALD equipped with a glove box to meet deposition needs using anaerobic materials that react with oxidation and the atmosphere.

Characteristic

- Table-top ALD with acrylic glovebox for vacuum evacuation and nitrogen venting.

- Deposition is possible on wafer geometries up to 4 inch.

- It is also equipped with a MAX 350°C heating mechanism. In tests with AL2O3, it has a film thickness distribution performance of less than 3% within Φ100 mm.

- A large handle is attached at the main unit as a portable tabletop system.

Uses

Table-top ALD (atomic layer deposition) system for research and development.

SAL3000 (ALD Equipment)

In addition to the conventional depo-down type specification, a ‘depo-up’ type is available to further reduce particle adhesion to the substrate.

Characteristic

- It enables uniform, pinhole-free layer deposition with a thickness distribution performance of ±3% for substrate sizes of ø100 mm or less.

- You can choose between the SAL3000+D depo-down (substrate face-up) or SAL3000+U depo-up (substrate face-down).

- The touch panel is positioned at an elevated angle and designed for better visibility and easy operation.

Uses

ALD (Atomic Layer Deposition) system for research and development.

For more information about ALD.

Evaporation equipment for depositing films on substrates by evaporating metallic materials installed in a heat source.

SEV2000Plus (Small Evaporation System FOR R&D)

Evaporation equipment designed to deposit metal or oxide films, etc. on substrates using a resistance-heated evaporation source and an EB gun.

Characteristic

- Various dedicated trays can be used to deposit films on a wide range of substrate sizes.

- The SEV2000Plus allows automatic exhaust operation from a touch screen and has various interlocks to prevent malfunctions.

- It can be combined with various devices.

- It thereby allows the substrate to be processed continuously without exposing it to the atmosphere.

Uses

The system is suitable for R&D, with automatic exhaust operations via a touch screen and a quartz crystal thickness gauge for film thickness control.

Annealing systems that enable film modification by heating wafers to high temperatures in a vacuum.

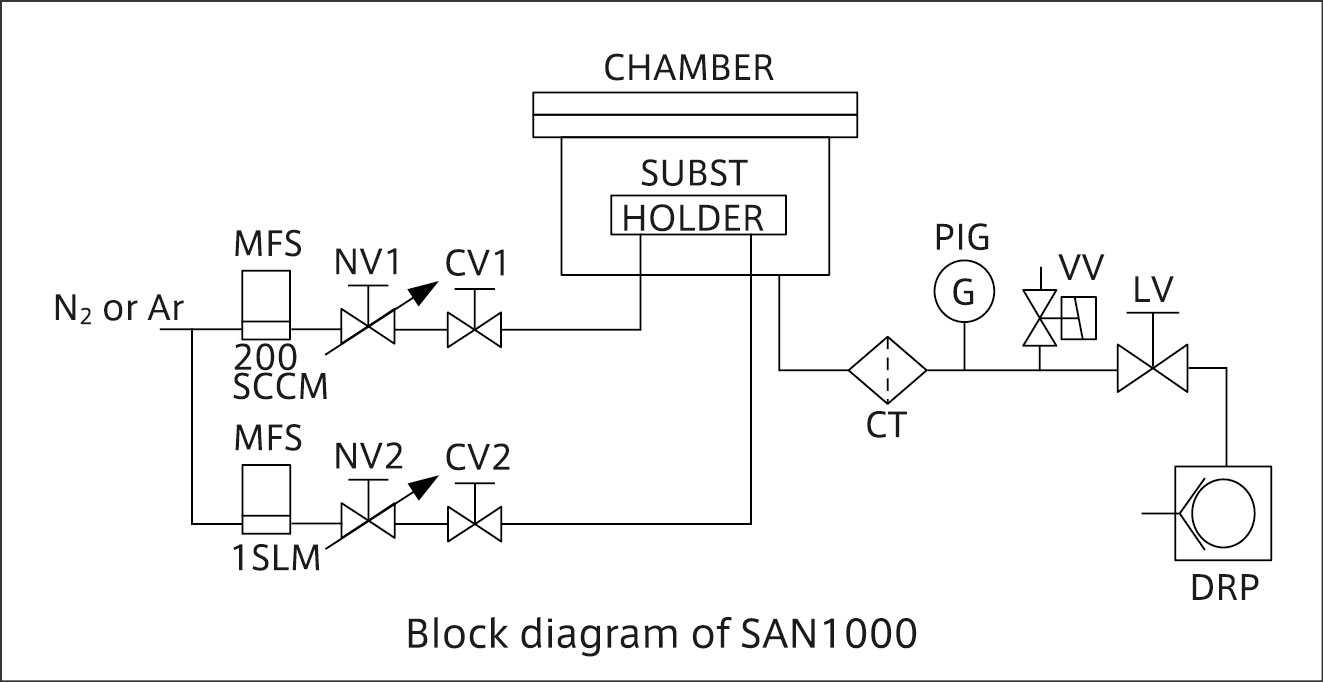

SAN1000 (Desktop Annealing・Nitriding Treatment Equipment)

This model is a table-top type small batch system and is equipped with a cooling mechanism that allows substrates to be taken out after processing in a short time.

Characteristic

- It enables substrate heat treatment by dry scroll pump.

- Rapid cooling is also possible due to the combination of a water-cooled cold-wall structure and a substrate-cooling gas mechanism.

- The optimized PID algorithm provides excellent temperature control.

Uses

This model is the table-top type system and it can control the pressure during high-temperature heat treatment (annealing) and heat treatment by introducing inert gas to the substrate.

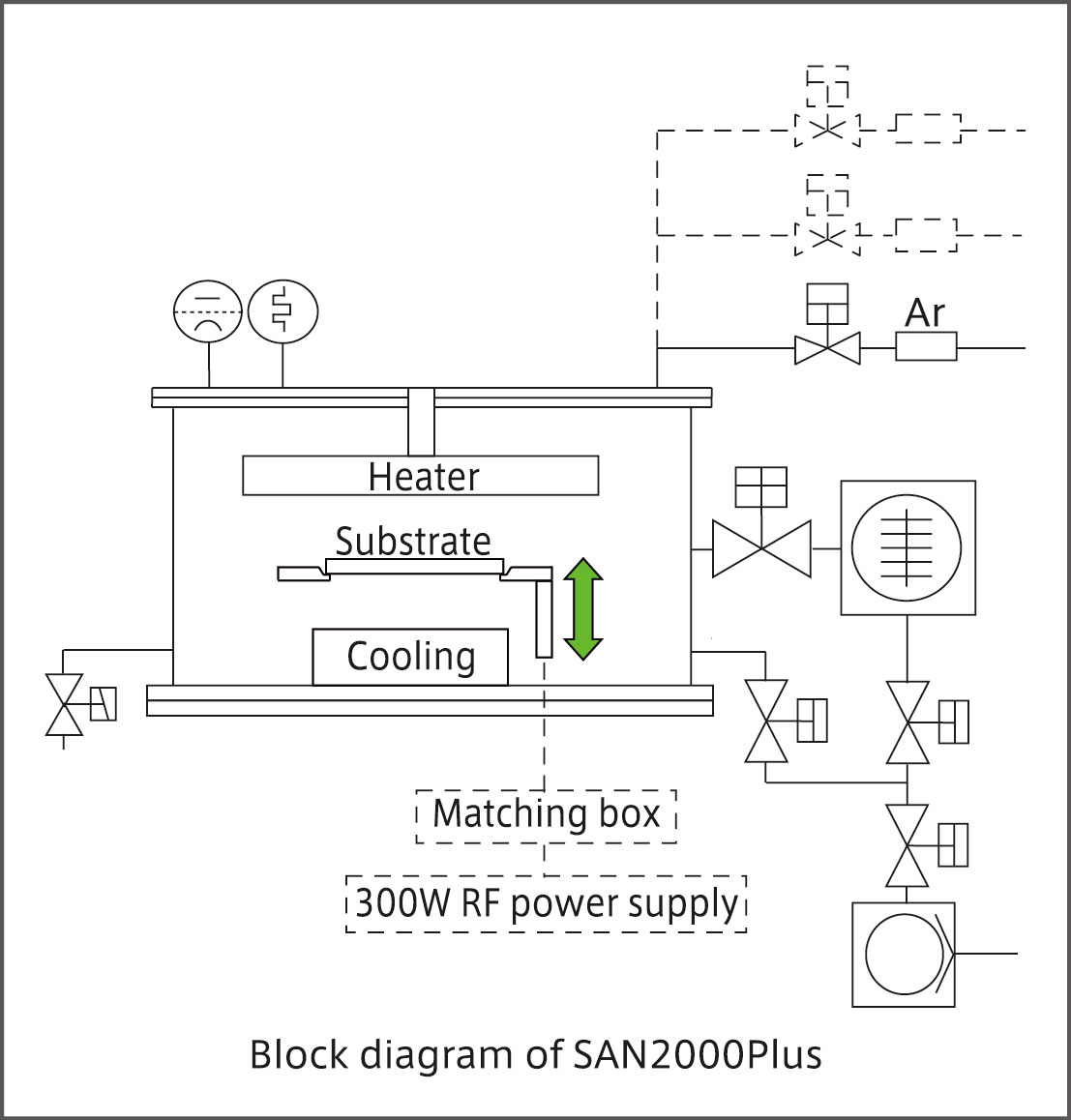

SAN2000Plus (Annealing system)

Substrates up to 4 inch can be heat-treated in a vacuum or in a clean environment with vacuum or inert gas atmosphere by means of powerful infrared radiation.

Characteristic

- The SAN2000Plus enables substrate heat treatment in a high vacuum condition obtained by turbo molecular pump.

- Heating control from 200°C to MAX 1000°C and cooling times can be programmed in up to 19 steps and 30 recipes.

- High-speed cooling is also applicable due to the combination of a water-cooled cold-wall structure and a substrate-cooling gas mechanism.

Uses

By adding plasma process technology that can remove organic and metal films from the substrate surface and modify the surface, this single unit can be used for both pre- and post-processing of substrate deposition.

Summary

We manufacture vacuum equipment and provides vacuum and piping components required to configure vacuum equipment and vacuum facilities, such as annealing equipment for film quality improvement applications after film deposition as vacuum equipment.

We also offer support for servicing, repairs and modifications, so please contact us.